| Availability: | |

|---|---|

| Quantity: | |

Metal Separation Equipment

It applies to plastic, pharmaceutical, food, chemical, electronic, electrical and other industries of raw materials, degraded materials, reclaimed materials for metal detection and separation.It is able to quickly detect and automatically separate iron, copper, aluminum, stainless steel and other metal impurities from materials.It can also be installed on injection molding machine, extruder and other equipment.

The advantages of using metal separator

1.Protection of production equipments

2.Impove efficiency greatly

3.Improve raw material utilization ratio

4.Improve quality of production

5.Decrease cost of maintaining and loss of downtime

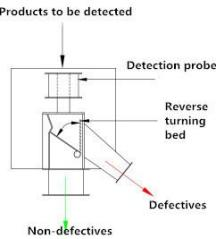

PEC2005 Series metal separator

PEC2005A Free fall pipeline metal separator (Main body)

PEC2005A economical metal separator adopts German technology.It has high sensitivity and reliability; it is used to separate magnetic and non-magnetic metals from free fall bulk materials and ensure product quality;Integrated metal foreign body rapid elimination system, it’s suitable for testing bulk products.

Application

It applies to plastic particles,degraded materials,reclaimed materials for metal detection and separation.It is able to quickly detect and automatically separate iron, copper,aluminum,stainless steel and other metal impurities from materials.It can also be installed in the injection molding machine,extruder and other equipment.

Product features

1.Avariety of apertures can be chosen, which can meet all practical applications,including product specification,requests of sensitivity,working flow.

2.Detected material characteristics:Bulk material, dry, good flowability, powder particle

3.Quick connector and air tight flange can be chosen to achieve quick installation and disassembly.

4. It’s compact and easy to install and integrate into existing pipelines.

5. It can also work with the injection molding machine, extruder and other equipment.

Specification parameters:

Model | Dimension (Фmm) | Sensitivity | air compression | Max.through put(L/h) | Material temperature | Defectives eliminated time | Installation height (mm) | |

FeΦ | SUSΦ | |||||||

PEC2005-35 | 35 | 0.3mm | 0.5mm | 3~5Bar | 400 | < 80℃ | 0.3~5s | |

PEC2005-50 | 50 | 0.5mm | 1.0mm | 3~5Bar | 2000 | < 80℃ | 0.3~5s | |

PEC2005-70 | 70 | 0.7mm | 1.2mm | 3~5Bar | 5000 | < 80℃ | 0.3~5s | |

PEC2005- 100 | 100 | 1.0mm | 1.5mm | 3~5Bar | 12000 | < 80℃ | 0.3~5s | 473 |

PEC2005- 120 | 120 | 1.2mm | 2.0mm | 3~5Bar | 16000 | < 80℃ | 0.3~5s | |

PEC2005- 150 | 150 | 1.5mm | 2.5mm | 3~5Bar | 25000 | < 80℃ | 0.3~5s | 600 |

PEC2005-200 | 200 | 2.0mm | 3.0mm | 3~5Bar | 44000 | < 80℃ | 0.3~5s | 922 |

PEC2005-250 | 250 | 2.5mm | 3.5mm | 3~5Bar | 69000 | < 80℃ | 0.3~5s | 948 |

Metal Separation Equipment

It applies to plastic, pharmaceutical, food, chemical, electronic, electrical and other industries of raw materials, degraded materials, reclaimed materials for metal detection and separation.It is able to quickly detect and automatically separate iron, copper, aluminum, stainless steel and other metal impurities from materials.It can also be installed on injection molding machine, extruder and other equipment.

The advantages of using metal separator

1.Protection of production equipments

2.Impove efficiency greatly

3.Improve raw material utilization ratio

4.Improve quality of production

5.Decrease cost of maintaining and loss of downtime

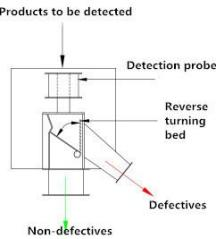

PEC2005 Series metal separator

PEC2005A Free fall pipeline metal separator (Main body)

PEC2005A economical metal separator adopts German technology.It has high sensitivity and reliability; it is used to separate magnetic and non-magnetic metals from free fall bulk materials and ensure product quality;Integrated metal foreign body rapid elimination system, it’s suitable for testing bulk products.

Application

It applies to plastic particles,degraded materials,reclaimed materials for metal detection and separation.It is able to quickly detect and automatically separate iron, copper,aluminum,stainless steel and other metal impurities from materials.It can also be installed in the injection molding machine,extruder and other equipment.

Product features

1.Avariety of apertures can be chosen, which can meet all practical applications,including product specification,requests of sensitivity,working flow.

2.Detected material characteristics:Bulk material, dry, good flowability, powder particle

3.Quick connector and air tight flange can be chosen to achieve quick installation and disassembly.

4. It’s compact and easy to install and integrate into existing pipelines.

5. It can also work with the injection molding machine, extruder and other equipment.

Specification parameters:

Model | Dimension (Фmm) | Sensitivity | air compression | Max.through put(L/h) | Material temperature | Defectives eliminated time | Installation height (mm) | |

FeΦ | SUSΦ | |||||||

PEC2005-35 | 35 | 0.3mm | 0.5mm | 3~5Bar | 400 | < 80℃ | 0.3~5s | |

PEC2005-50 | 50 | 0.5mm | 1.0mm | 3~5Bar | 2000 | < 80℃ | 0.3~5s | |

PEC2005-70 | 70 | 0.7mm | 1.2mm | 3~5Bar | 5000 | < 80℃ | 0.3~5s | |

PEC2005- 100 | 100 | 1.0mm | 1.5mm | 3~5Bar | 12000 | < 80℃ | 0.3~5s | 473 |

PEC2005- 120 | 120 | 1.2mm | 2.0mm | 3~5Bar | 16000 | < 80℃ | 0.3~5s | |

PEC2005- 150 | 150 | 1.5mm | 2.5mm | 3~5Bar | 25000 | < 80℃ | 0.3~5s | 600 |

PEC2005-200 | 200 | 2.0mm | 3.0mm | 3~5Bar | 44000 | < 80℃ | 0.3~5s | 922 |

PEC2005-250 | 250 | 2.5mm | 3.5mm | 3~5Bar | 69000 | < 80℃ | 0.3~5s | 948 |