Checkweigher substantiates the extensive know-how that the company has accumulated in weighing technology over the years. By including a high-precision weight checking function in the production line, your product quality can improve without any decline in efficiency. The series provides a whole range of features for handling different products, and incorporate new functions in response to modern necessities.

Easy Integration: adjustable height, modular design

Sturdy and robust construction: Stainless Steel 304, built to last

Easy to use: on board touch screen operating system is easy to use with user password protection

Easy to clean: detachable belt easy to to take apart for cleaning and set up. •Variable Speed: Speed configurable based on application

High Speed and Accuracy: equipped with high grade sensor and load cell with ultra fast processor for excellent accuracy and speed

Zero Trace: Manual and Automatic Calibration, increase accuracy

Report and Data Exportation: Built-in real time report, exportable to Excel file, storing up 1 year production data in USB disk

Connectivity: standard ports for data exportation and connect to PC

Self-learning: no need to calibration, system will find the best set up for the product. Configurable up to 2000 product settings

Different Detection Modes: Default Mode, Static Mode, Power saving mode

Faulty report: The system can detect and report faulty part of the system makes it easy to diagnose problems

Output Ports: RS-485 and RS-232, able to Connect with printers and label machines

Specification

Basic Parameters of CW Checkweigher

| Model | CW-2512 | CW-2515 | CW-4021 | CW-4525 | CW-4530 | CW-6240 | CW-9050 | |

| Single Weighing Scope | ≤200g | ≤200g | ≤ 1000g | ≤ 1000g | ≤3000g | ≤ 15kg | ≤40kg | |

| Accuracy | ±0. 1g | ±0.2g~±0.5g | ±0.3g~± 1g | ±0.3g~± 1g | ±0.5g~±2g | ±2g~± 10g | ±5g~±30g | |

| Minimum scale | 0.01g | 0.01g | 0. 1g | 0. 1g | 0. 1g | 1g | 1g | |

| Conveying Speed | 20-60m/min | 20-60m/min | 30~ 90m/min | 30~ 90m/mi | 30~ 90m/min | 30-70m/mi n | 20~35m/min | |

| Max Speed | 180 pcs/min | 180 pcs/min | 160 pcs/min | 160 pcs/min | 80 pcs/min | 60 pcs/min | 30 pcs/min | |

Products to be weighed | Length | ≤ 100mm | ≤ 150mm | ≤280mm | ≤280mm | ≤300mm | ≤450mm | ≤650mm |

| Width | ≤ 100mm | ≤ 120mm | ≤200mm | ≤250mm | ≤290mm | ≤390mm | ≤490mm | |

Conveyo r Belt’s size of Checkw eigher | Length | 250mm | 250mm | 400mm | 450mm | 450mm | 620mm | 900mm |

| Width | 120mm | 150mm | 210mm | 250mm | 300mm | 400mm | 500mm | |

| Rated Power | 0. 1KW | 0. 1KW | 0. 15KW | 0. 15KW | 0.4KW | 0.4KW | 0.4KW | |

| Power Supply | AC220V± 10% 50HZ (60HZ) | |||||||

| Rejection | Air Blowing/Push Lever/Swing Arm | |||||||

| Controlling System | High Speed A/D Sample Controller | |||||||

| Operating Panel | Touch Screen | |||||||

| Preset Products’ name | 99 | |||||||

| Operating Direction | Facing Machine, from Left to Right | |||||||

| External Gas Source | 0.6- 1Mpa | |||||||

| Interface of Air Pressure | Φ8mm | |||||||

| Working Environment | Temperature: 0℃~40℃,Humidity: 30%~95% | |||||||

| Material of Machine | SUS304 | |||||||

Metal detection equipment

AEC500C Series digital intelligent conveyor belt metal detector can be used in food, pharmaceutical, chemical, textile, garment, toy paper-making, hygienic products, electronics, renewable resources industry etc, applying to detect broken needles, iron wires, metals (such as Plumbum; Copper; Aluminum; Stannum; SUS etc.) that mixed or left with products, raw materials. Using metal detector can help relative corporations pass HACCP,GMP, FDA,QS, ISO9001 certificate.

AEC500C Series Digital Intelligent Conveyor Belt Metal Detector

Touch Screen Type

Touch Screen Type

AEC500C Series digital intelligent metal detector is a new generation of intelligent metal detector adopted digital intelligent technology, which realizes full digitally and intelligently on metal detection.With excellent performances and easy operation to improve efficiency greatly.

Application:

AEC500C Series digital intelligent conveyor belt metal detector can be used in food, pharmaceutical, chemical, textile, garment, toy paper-making, hygienic products, electronics, renewable resources industry etc, applying to detect broken needles, iron wires, metals (such as Plumbum; Copper; Aluminum; Stannum; SUS etc.) that mixed or left with products, raw materials. Using metal detector can help relative corporations pass HACCP,GMP, FDA,QS, ISO9001 certificate.

Product Features:

1. Operating system adopts highly human-oriented and intelligent design and has the function of one-bottom self-learning. The machine can set and store product parameters automatically and precisely when the products to be detected passing metal detector according to set procedure, no need to adjust by human and is easy to operate.

2. Detector is made by COSO unique materials and manufacturing techniques, possessing high sensitivity, strong ability for anti-interference, stable performances, and life span more than 10 years.

3. Having memory function for 100 kinds of products parameters; that is, metal detector can store 100 kinds of products parameters, and once the products parameters are set, no need to adjust again.

4. Metal detector can automatically detect faults when booting and has the function of prompt, which can effectively eliminate invalid detection.

5. The whole machine adopts modular design and installation, which benefits for assembly and disassembly, having advantages of convenient maintenance and low cost for maintenance.

6. Customization can be provided according to detecting products’ sizes, weight and characteristics in order to achieve best detection results.

7. The automatic conveying system, reject system and control system can be customized according to production line’s features, which can enhance production efficiency.

8. Customization for waterproof, dust-proof and explosion-proof needs can be provided according to the environment of production line in order to protect usage safety.

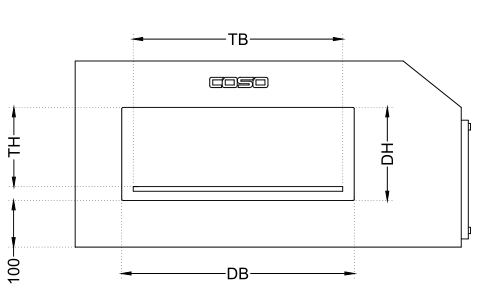

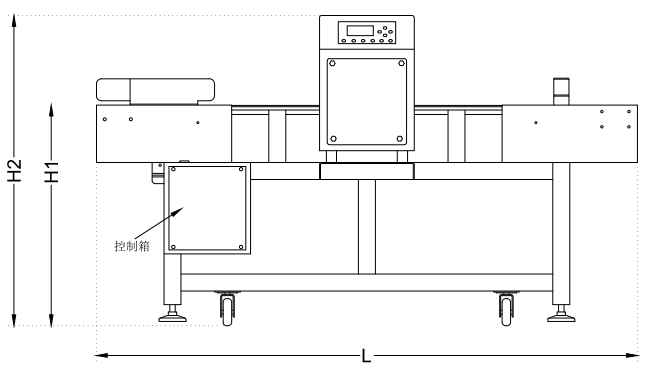

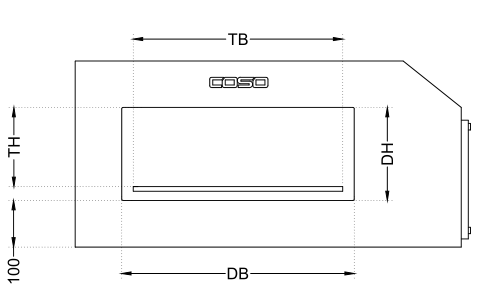

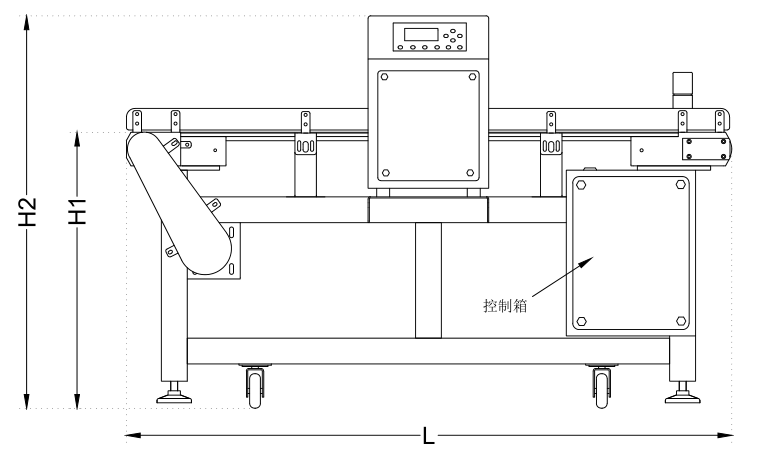

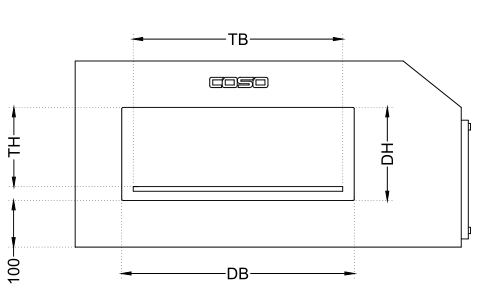

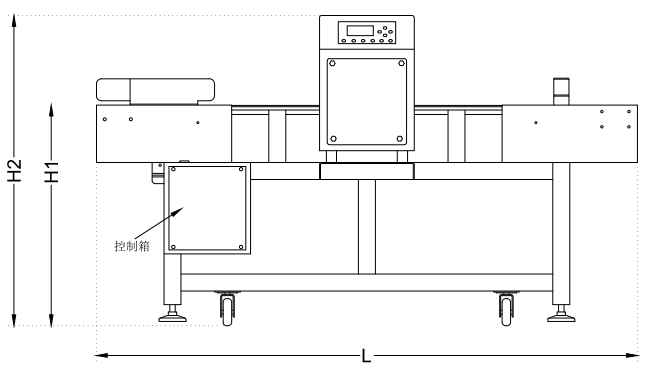

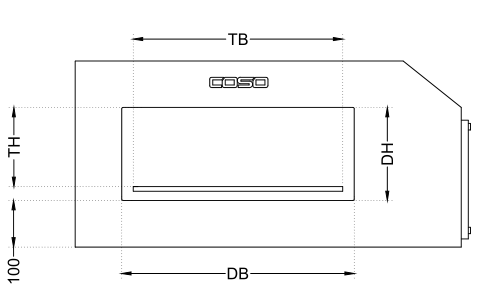

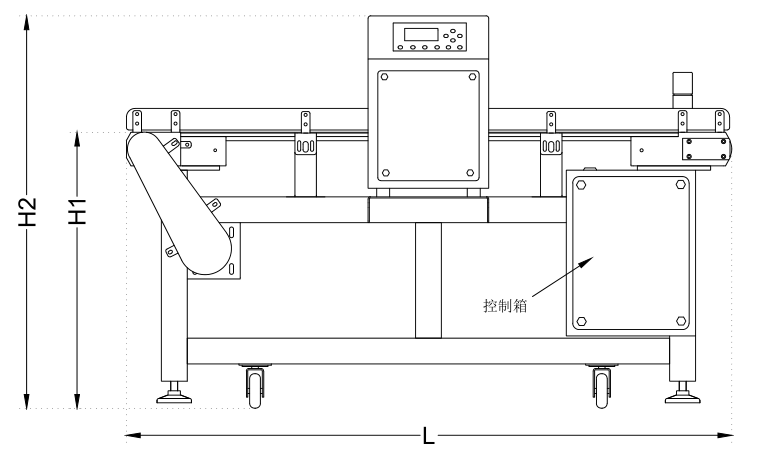

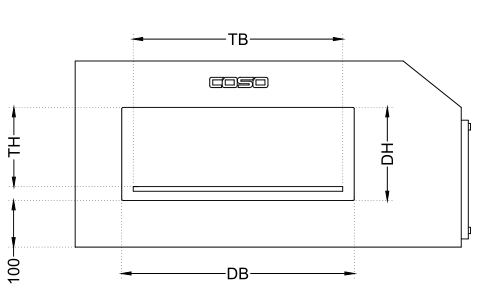

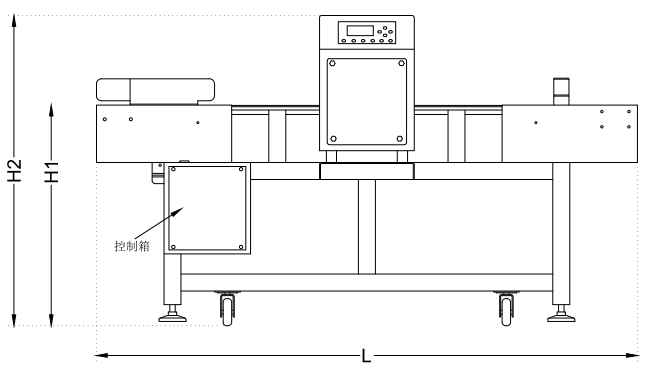

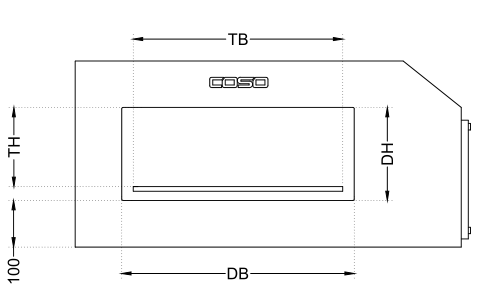

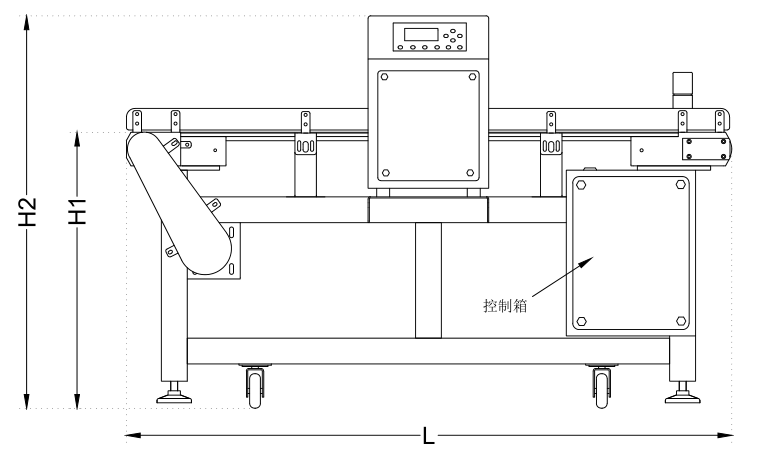

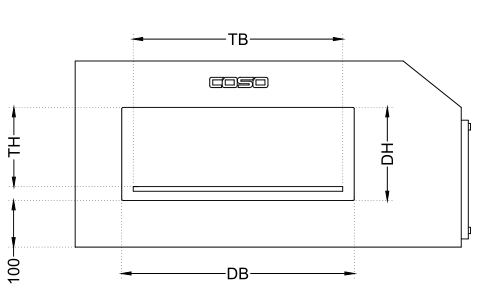

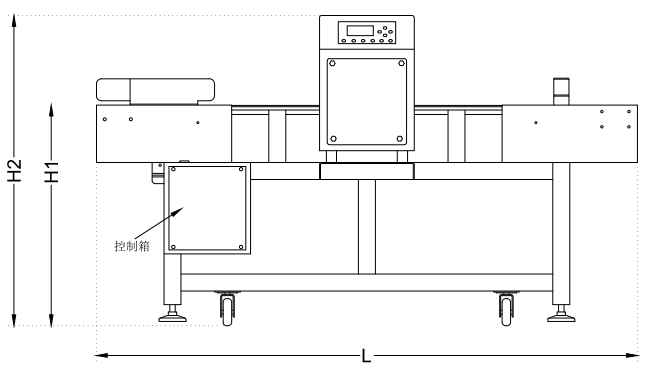

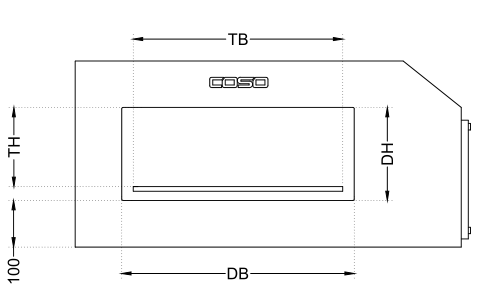

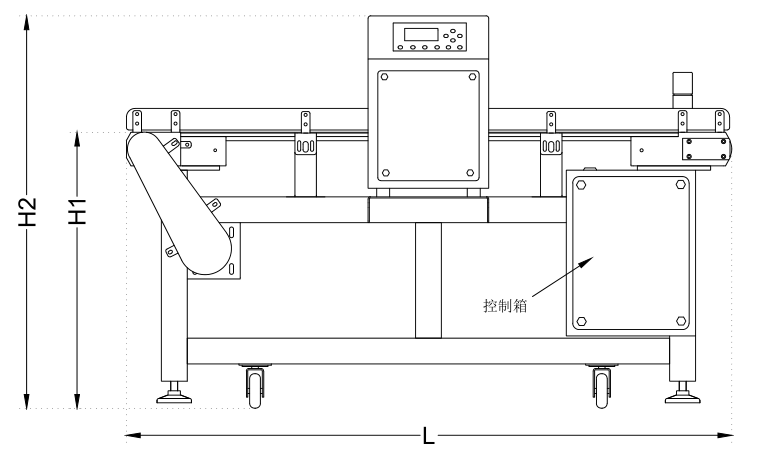

Structure:

DB: Width of detector H1:Height from conveyor belt to the ground

DH:Height of detector H2:Height of whole machine

TB:Passing width L:Length of conveyor belt

TH:Passing height W:Height of whole machine

For Lightweight Products

For Heavy-weight Products

Checkweigher substantiates the extensive know-how that the company has accumulated in weighing technology over the years. By including a high-precision weight checking function in the production line, your product quality can improve without any decline in efficiency. The series provides a whole range of features for handling different products, and incorporate new functions in response to modern necessities.

Easy Integration: adjustable height, modular design

Sturdy and robust construction: Stainless Steel 304, built to last

Easy to use: on board touch screen operating system is easy to use with user password protection

Easy to clean: detachable belt easy to to take apart for cleaning and set up. •Variable Speed: Speed configurable based on application

High Speed and Accuracy: equipped with high grade sensor and load cell with ultra fast processor for excellent accuracy and speed

Zero Trace: Manual and Automatic Calibration, increase accuracy

Report and Data Exportation: Built-in real time report, exportable to Excel file, storing up 1 year production data in USB disk

Connectivity: standard ports for data exportation and connect to PC

Self-learning: no need to calibration, system will find the best set up for the product. Configurable up to 2000 product settings

Different Detection Modes: Default Mode, Static Mode, Power saving mode

Faulty report: The system can detect and report faulty part of the system makes it easy to diagnose problems

Output Ports: RS-485 and RS-232, able to Connect with printers and label machines

Specification

Basic Parameters of CW Checkweigher

| Model | CW-2512 | CW-2515 | CW-4021 | CW-4525 | CW-4530 | CW-6240 | CW-9050 | |

| Single Weighing Scope | ≤200g | ≤200g | ≤ 1000g | ≤ 1000g | ≤3000g | ≤ 15kg | ≤40kg | |

| Accuracy | ±0. 1g | ±0.2g~±0.5g | ±0.3g~± 1g | ±0.3g~± 1g | ±0.5g~±2g | ±2g~± 10g | ±5g~±30g | |

| Minimum scale | 0.01g | 0.01g | 0. 1g | 0. 1g | 0. 1g | 1g | 1g | |

| Conveying Speed | 20-60m/min | 20-60m/min | 30~ 90m/min | 30~ 90m/mi | 30~ 90m/min | 30-70m/mi n | 20~35m/min | |

| Max Speed | 180 pcs/min | 180 pcs/min | 160 pcs/min | 160 pcs/min | 80 pcs/min | 60 pcs/min | 30 pcs/min | |

Products to be weighed | Length | ≤ 100mm | ≤ 150mm | ≤280mm | ≤280mm | ≤300mm | ≤450mm | ≤650mm |

| Width | ≤ 100mm | ≤ 120mm | ≤200mm | ≤250mm | ≤290mm | ≤390mm | ≤490mm | |

Conveyo r Belt’s size of Checkw eigher | Length | 250mm | 250mm | 400mm | 450mm | 450mm | 620mm | 900mm |

| Width | 120mm | 150mm | 210mm | 250mm | 300mm | 400mm | 500mm | |

| Rated Power | 0. 1KW | 0. 1KW | 0. 15KW | 0. 15KW | 0.4KW | 0.4KW | 0.4KW | |

| Power Supply | AC220V± 10% 50HZ (60HZ) | |||||||

| Rejection | Air Blowing/Push Lever/Swing Arm | |||||||

| Controlling System | High Speed A/D Sample Controller | |||||||

| Operating Panel | Touch Screen | |||||||

| Preset Products’ name | 99 | |||||||

| Operating Direction | Facing Machine, from Left to Right | |||||||

| External Gas Source | 0.6- 1Mpa | |||||||

| Interface of Air Pressure | Φ8mm | |||||||

| Working Environment | Temperature: 0℃~40℃,Humidity: 30%~95% | |||||||

| Material of Machine | SUS304 | |||||||

Metal detection equipment

AEC500C Series digital intelligent conveyor belt metal detector can be used in food, pharmaceutical, chemical, textile, garment, toy paper-making, hygienic products, electronics, renewable resources industry etc, applying to detect broken needles, iron wires, metals (such as Plumbum; Copper; Aluminum; Stannum; SUS etc.) that mixed or left with products, raw materials. Using metal detector can help relative corporations pass HACCP,GMP, FDA,QS, ISO9001 certificate.

AEC500C Series Digital Intelligent Conveyor Belt Metal Detector

Touch Screen Type

Touch Screen Type

AEC500C Series digital intelligent metal detector is a new generation of intelligent metal detector adopted digital intelligent technology, which realizes full digitally and intelligently on metal detection.With excellent performances and easy operation to improve efficiency greatly.

Application:

AEC500C Series digital intelligent conveyor belt metal detector can be used in food, pharmaceutical, chemical, textile, garment, toy paper-making, hygienic products, electronics, renewable resources industry etc, applying to detect broken needles, iron wires, metals (such as Plumbum; Copper; Aluminum; Stannum; SUS etc.) that mixed or left with products, raw materials. Using metal detector can help relative corporations pass HACCP,GMP, FDA,QS, ISO9001 certificate.

Product Features:

1. Operating system adopts highly human-oriented and intelligent design and has the function of one-bottom self-learning. The machine can set and store product parameters automatically and precisely when the products to be detected passing metal detector according to set procedure, no need to adjust by human and is easy to operate.

2. Detector is made by COSO unique materials and manufacturing techniques, possessing high sensitivity, strong ability for anti-interference, stable performances, and life span more than 10 years.

3. Having memory function for 100 kinds of products parameters; that is, metal detector can store 100 kinds of products parameters, and once the products parameters are set, no need to adjust again.

4. Metal detector can automatically detect faults when booting and has the function of prompt, which can effectively eliminate invalid detection.

5. The whole machine adopts modular design and installation, which benefits for assembly and disassembly, having advantages of convenient maintenance and low cost for maintenance.

6. Customization can be provided according to detecting products’ sizes, weight and characteristics in order to achieve best detection results.

7. The automatic conveying system, reject system and control system can be customized according to production line’s features, which can enhance production efficiency.

8. Customization for waterproof, dust-proof and explosion-proof needs can be provided according to the environment of production line in order to protect usage safety.

Structure:

DB: Width of detector H1:Height from conveyor belt to the ground

DH:Height of detector H2:Height of whole machine

TB:Passing width L:Length of conveyor belt

TH:Passing height W:Height of whole machine

For Lightweight Products

For Heavy-weight Products

Checkweigher substantiates the extensive know-how that the company has accumulated in weighing technology over the years. By including a high-precision weight checking function in the production line, your product quality can improve without any decline in efficiency. The series provides a whole range of features for handling different products, and incorporate new functions in response to modern necessities.

Easy Integration: adjustable height, modular design

Sturdy and robust construction: Stainless Steel 304, built to last

Easy to use: on board touch screen operating system is easy to use with user password protection

Easy to clean: detachable belt easy to to take apart for cleaning and set up. •Variable Speed: Speed configurable based on application

High Speed and Accuracy: equipped with high grade sensor and load cell with ultra fast processor for excellent accuracy and speed

Zero Trace: Manual and Automatic Calibration, increase accuracy

Report and Data Exportation: Built-in real time report, exportable to Excel file, storing up 1 year production data in USB disk

Connectivity: standard ports for data exportation and connect to PC

Self-learning: no need to calibration, system will find the best set up for the product. Configurable up to 2000 product settings

Different Detection Modes: Default Mode, Static Mode, Power saving mode

Faulty report: The system can detect and report faulty part of the system makes it easy to diagnose problems

Output Ports: RS-485 and RS-232, able to Connect with printers and label machines

Specification

Basic Parameters of CW Checkweigher

| Model | CW-2512 | CW-2515 | CW-4021 | CW-4525 | CW-4530 | CW-6240 | CW-9050 | |

| Single Weighing Scope | ≤200g | ≤200g | ≤ 1000g | ≤ 1000g | ≤3000g | ≤ 15kg | ≤40kg | |

| Accuracy | ±0. 1g | ±0.2g~±0.5g | ±0.3g~± 1g | ±0.3g~± 1g | ±0.5g~±2g | ±2g~± 10g | ±5g~±30g | |

| Minimum scale | 0.01g | 0.01g | 0. 1g | 0. 1g | 0. 1g | 1g | 1g | |

| Conveying Speed | 20-60m/min | 20-60m/min | 30~ 90m/min | 30~ 90m/mi | 30~ 90m/min | 30-70m/mi n | 20~35m/min | |

| Max Speed | 180 pcs/min | 180 pcs/min | 160 pcs/min | 160 pcs/min | 80 pcs/min | 60 pcs/min | 30 pcs/min | |

Products to be weighed | Length | ≤ 100mm | ≤ 150mm | ≤280mm | ≤280mm | ≤300mm | ≤450mm | ≤650mm |

| Width | ≤ 100mm | ≤ 120mm | ≤200mm | ≤250mm | ≤290mm | ≤390mm | ≤490mm | |

Conveyo r Belt’s size of Checkw eigher | Length | 250mm | 250mm | 400mm | 450mm | 450mm | 620mm | 900mm |

| Width | 120mm | 150mm | 210mm | 250mm | 300mm | 400mm | 500mm | |

| Rated Power | 0. 1KW | 0. 1KW | 0. 15KW | 0. 15KW | 0.4KW | 0.4KW | 0.4KW | |

| Power Supply | AC220V± 10% 50HZ (60HZ) | |||||||

| Rejection | Air Blowing/Push Lever/Swing Arm | |||||||

| Controlling System | High Speed A/D Sample Controller | |||||||

| Operating Panel | Touch Screen | |||||||

| Preset Products’ name | 99 | |||||||

| Operating Direction | Facing Machine, from Left to Right | |||||||

| External Gas Source | 0.6- 1Mpa | |||||||

| Interface of Air Pressure | Φ8mm | |||||||

| Working Environment | Temperature: 0℃~40℃,Humidity: 30%~95% | |||||||

| Material of Machine | SUS304 | |||||||

Metal detection equipment

AEC500C Series digital intelligent conveyor belt metal detector can be used in food, pharmaceutical, chemical, textile, garment, toy paper-making, hygienic products, electronics, renewable resources industry etc, applying to detect broken needles, iron wires, metals (such as Plumbum; Copper; Aluminum; Stannum; SUS etc.) that mixed or left with products, raw materials. Using metal detector can help relative corporations pass HACCP,GMP, FDA,QS, ISO9001 certificate.

AEC500C Series Digital Intelligent Conveyor Belt Metal Detector

Touch Screen Type

Touch Screen Type

AEC500C Series digital intelligent metal detector is a new generation of intelligent metal detector adopted digital intelligent technology, which realizes full digitally and intelligently on metal detection.With excellent performances and easy operation to improve efficiency greatly.

Application:

AEC500C Series digital intelligent conveyor belt metal detector can be used in food, pharmaceutical, chemical, textile, garment, toy paper-making, hygienic products, electronics, renewable resources industry etc, applying to detect broken needles, iron wires, metals (such as Plumbum; Copper; Aluminum; Stannum; SUS etc.) that mixed or left with products, raw materials. Using metal detector can help relative corporations pass HACCP,GMP, FDA,QS, ISO9001 certificate.

Product Features:

1. Operating system adopts highly human-oriented and intelligent design and has the function of one-bottom self-learning. The machine can set and store product parameters automatically and precisely when the products to be detected passing metal detector according to set procedure, no need to adjust by human and is easy to operate.

2. Detector is made by COSO unique materials and manufacturing techniques, possessing high sensitivity, strong ability for anti-interference, stable performances, and life span more than 10 years.

3. Having memory function for 100 kinds of products parameters; that is, metal detector can store 100 kinds of products parameters, and once the products parameters are set, no need to adjust again.

4. Metal detector can automatically detect faults when booting and has the function of prompt, which can effectively eliminate invalid detection.

5. The whole machine adopts modular design and installation, which benefits for assembly and disassembly, having advantages of convenient maintenance and low cost for maintenance.

6. Customization can be provided according to detecting products’ sizes, weight and characteristics in order to achieve best detection results.

7. The automatic conveying system, reject system and control system can be customized according to production line’s features, which can enhance production efficiency.

8. Customization for waterproof, dust-proof and explosion-proof needs can be provided according to the environment of production line in order to protect usage safety.

Structure:

DB: Width of detector H1:Height from conveyor belt to the ground

DH:Height of detector H2:Height of whole machine

TB:Passing width L:Length of conveyor belt

TH:Passing height W:Height of whole machine

For Lightweight Products

For Heavy-weight Products

Checkweigher substantiates the extensive know-how that the company has accumulated in weighing technology over the years. By including a high-precision weight checking function in the production line, your product quality can improve without any decline in efficiency. The series provides a whole range of features for handling different products, and incorporate new functions in response to modern necessities.

Easy Integration: adjustable height, modular design

Sturdy and robust construction: Stainless Steel 304, built to last

Easy to use: on board touch screen operating system is easy to use with user password protection

Easy to clean: detachable belt easy to to take apart for cleaning and set up. •Variable Speed: Speed configurable based on application

High Speed and Accuracy: equipped with high grade sensor and load cell with ultra fast processor for excellent accuracy and speed

Zero Trace: Manual and Automatic Calibration, increase accuracy

Report and Data Exportation: Built-in real time report, exportable to Excel file, storing up 1 year production data in USB disk

Connectivity: standard ports for data exportation and connect to PC

Self-learning: no need to calibration, system will find the best set up for the product. Configurable up to 2000 product settings

Different Detection Modes: Default Mode, Static Mode, Power saving mode

Faulty report: The system can detect and report faulty part of the system makes it easy to diagnose problems

Output Ports: RS-485 and RS-232, able to Connect with printers and label machines

Specification

Basic Parameters of CW Checkweigher

| Model | CW-2512 | CW-2515 | CW-4021 | CW-4525 | CW-4530 | CW-6240 | CW-9050 | |

| Single Weighing Scope | ≤200g | ≤200g | ≤ 1000g | ≤ 1000g | ≤3000g | ≤ 15kg | ≤40kg | |

| Accuracy | ±0. 1g | ±0.2g~±0.5g | ±0.3g~± 1g | ±0.3g~± 1g | ±0.5g~±2g | ±2g~± 10g | ±5g~±30g | |

| Minimum scale | 0.01g | 0.01g | 0. 1g | 0. 1g | 0. 1g | 1g | 1g | |

| Conveying Speed | 20-60m/min | 20-60m/min | 30~ 90m/min | 30~ 90m/mi | 30~ 90m/min | 30-70m/mi n | 20~35m/min | |

| Max Speed | 180 pcs/min | 180 pcs/min | 160 pcs/min | 160 pcs/min | 80 pcs/min | 60 pcs/min | 30 pcs/min | |

Products to be weighed | Length | ≤ 100mm | ≤ 150mm | ≤280mm | ≤280mm | ≤300mm | ≤450mm | ≤650mm |

| Width | ≤ 100mm | ≤ 120mm | ≤200mm | ≤250mm | ≤290mm | ≤390mm | ≤490mm | |

Conveyo r Belt’s size of Checkw eigher | Length | 250mm | 250mm | 400mm | 450mm | 450mm | 620mm | 900mm |

| Width | 120mm | 150mm | 210mm | 250mm | 300mm | 400mm | 500mm | |

| Rated Power | 0. 1KW | 0. 1KW | 0. 15KW | 0. 15KW | 0.4KW | 0.4KW | 0.4KW | |

| Power Supply | AC220V± 10% 50HZ (60HZ) | |||||||

| Rejection | Air Blowing/Push Lever/Swing Arm | |||||||

| Controlling System | High Speed A/D Sample Controller | |||||||

| Operating Panel | Touch Screen | |||||||

| Preset Products’ name | 99 | |||||||

| Operating Direction | Facing Machine, from Left to Right | |||||||

| External Gas Source | 0.6- 1Mpa | |||||||

| Interface of Air Pressure | Φ8mm | |||||||

| Working Environment | Temperature: 0℃~40℃,Humidity: 30%~95% | |||||||

| Material of Machine | SUS304 | |||||||

Metal detection equipment

AEC500C Series digital intelligent conveyor belt metal detector can be used in food, pharmaceutical, chemical, textile, garment, toy paper-making, hygienic products, electronics, renewable resources industry etc, applying to detect broken needles, iron wires, metals (such as Plumbum; Copper; Aluminum; Stannum; SUS etc.) that mixed or left with products, raw materials. Using metal detector can help relative corporations pass HACCP,GMP, FDA,QS, ISO9001 certificate.

AEC500C Series Digital Intelligent Conveyor Belt Metal Detector

Touch Screen Type

Touch Screen Type

AEC500C Series digital intelligent metal detector is a new generation of intelligent metal detector adopted digital intelligent technology, which realizes full digitally and intelligently on metal detection.With excellent performances and easy operation to improve efficiency greatly.

Application:

AEC500C Series digital intelligent conveyor belt metal detector can be used in food, pharmaceutical, chemical, textile, garment, toy paper-making, hygienic products, electronics, renewable resources industry etc, applying to detect broken needles, iron wires, metals (such as Plumbum; Copper; Aluminum; Stannum; SUS etc.) that mixed or left with products, raw materials. Using metal detector can help relative corporations pass HACCP,GMP, FDA,QS, ISO9001 certificate.

Product Features:

1. Operating system adopts highly human-oriented and intelligent design and has the function of one-bottom self-learning. The machine can set and store product parameters automatically and precisely when the products to be detected passing metal detector according to set procedure, no need to adjust by human and is easy to operate.

2. Detector is made by COSO unique materials and manufacturing techniques, possessing high sensitivity, strong ability for anti-interference, stable performances, and life span more than 10 years.

3. Having memory function for 100 kinds of products parameters; that is, metal detector can store 100 kinds of products parameters, and once the products parameters are set, no need to adjust again.

4. Metal detector can automatically detect faults when booting and has the function of prompt, which can effectively eliminate invalid detection.

5. The whole machine adopts modular design and installation, which benefits for assembly and disassembly, having advantages of convenient maintenance and low cost for maintenance.

6. Customization can be provided according to detecting products’ sizes, weight and characteristics in order to achieve best detection results.

7. The automatic conveying system, reject system and control system can be customized according to production line’s features, which can enhance production efficiency.

8. Customization for waterproof, dust-proof and explosion-proof needs can be provided according to the environment of production line in order to protect usage safety.

Structure:

DB: Width of detector H1:Height from conveyor belt to the ground

DH:Height of detector H2:Height of whole machine

TB:Passing width L:Length of conveyor belt

TH:Passing height W:Height of whole machine

For Lightweight Products

For Heavy-weight Products