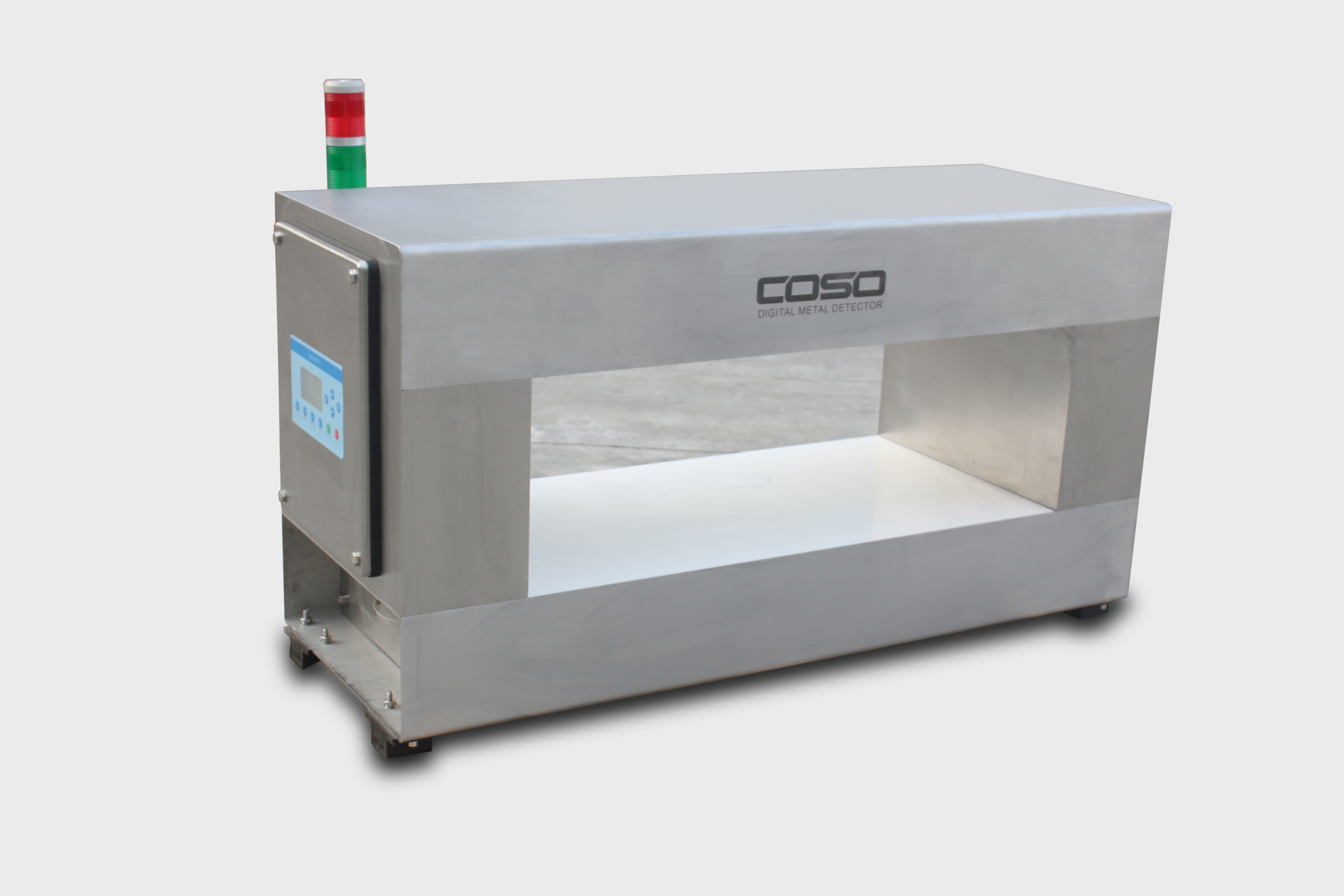

SEC series digital intelligent online metal detector can eliminate signal interference furthest from products themselves (like ore, coal, chemical, renewable resources, waste etc.) and conveyor belt itself by using DSP digital intelligent technology, at the same time, ensuring conveyor and products (like ore, coal, chemical, renewable resources, waste etc.) to pass detector, also can achieve perfect detection results.

Application:

Plastic, building material, wood, paper making, coal, textile, mines, cement, thermal power, chemical, chemical, waste processing and renewable resources industry etc. it is used for detecting bulk metallic impurities left or mixed with products, which can help avoid damage to working machines.

Features:

1. Using DSP digital intelligent technology deals with detection signal and interference signal, also can effectively and automatically control interference effects, possessing high detection sensitivity and strong anti-interference ability.

2. Having function of self-learning and memory, metal detector can automatically learn and memory products’ features; effectively eliminate “metal effect” that ore, coal itselfpossesses, besides, it can memory products’ parameters up to 100 kinds.

3. Adjustment ofproducts’ parameter is highly digital and easy to operate. By one-bottom self-learning can precisely set parameters automatically, no need for human to adjust and avoid complex debugging.

4. Metal detector has dialogue type LCD screen, menu, thin film switch bottom; convenient for operation.

5. Metal detector is waterproof, anti-vibration and has strong adaptability to environment and temperature changes.

6. The conveyor belt generally will be installed horizontally, but it can be applied to different angle according to your request.

7. The detector head can be separated, but the belt do not need to be cut.

8. When the impurities is detected,the metal detector will send the stopping signal from the intermediate relays to the conveyor belt system.

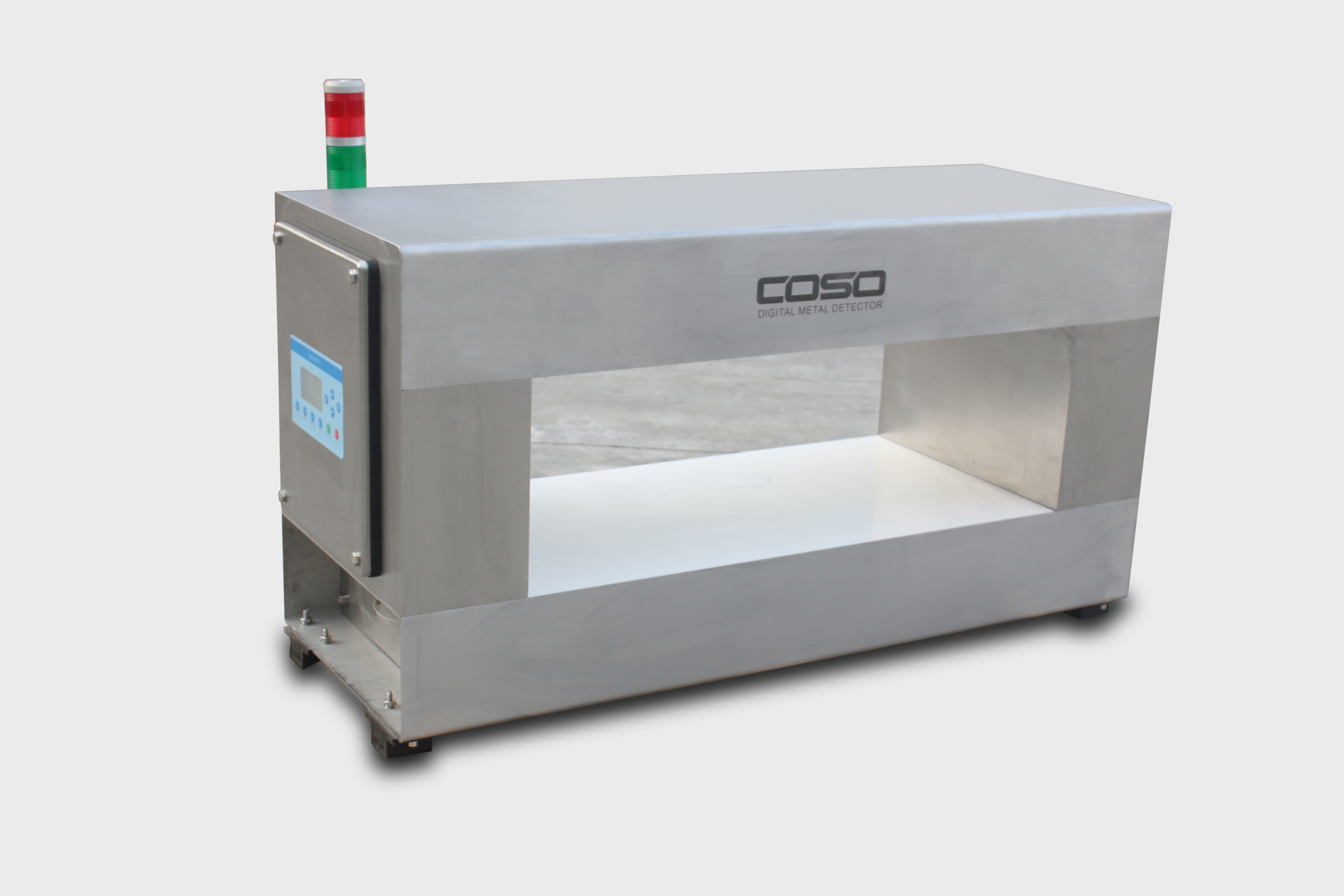

SEC series digital intelligent online metal detector can eliminate signal interference furthest from products themselves (like ore, coal, chemical, renewable resources, waste etc.) and conveyor belt itself by using DSP digital intelligent technology, at the same time, ensuring conveyor and products (like ore, coal, chemical, renewable resources, waste etc.) to pass detector, also can achieve perfect detection results.

Application:

Plastic, building material, wood, paper making, coal, textile, mines, cement, thermal power, chemical, chemical, waste processing and renewable resources industry etc. it is used for detecting bulk metallic impurities left or mixed with products, which can help avoid damage to working machines.

Features:

1. Using DSP digital intelligent technology deals with detection signal and interference signal, also can effectively and automatically control interference effects, possessing high detection sensitivity and strong anti-interference ability.

2. Having function of self-learning and memory, metal detector can automatically learn and memory products’ features; effectively eliminate “metal effect” that ore, coal itselfpossesses, besides, it can memory products’ parameters up to 100 kinds.

3. Adjustment ofproducts’ parameter is highly digital and easy to operate. By one-bottom self-learning can precisely set parameters automatically, no need for human to adjust and avoid complex debugging.

4. Metal detector has dialogue type LCD screen, menu, thin film switch bottom; convenient for operation.

5. Metal detector is waterproof, anti-vibration and has strong adaptability to environment and temperature changes.

6. The conveyor belt generally will be installed horizontally, but it can be applied to different angle according to your request.

7. The detector head can be separated, but the belt do not need to be cut.

8. When the impurities is detected,the metal detector will send the stopping signal from the intermediate relays to the conveyor belt system.

Specification

1.Structure:

Technical Parameter

Name | Parameter |

Detecting Height | 200mm (over 200mm, can be customized) |

Detecting Width | 500mm (over 500mm, can be customized) |

Sensitivity | Decided by the width and height of tunnel, refer to below sheet |

Power Supply | AC220V±10%,50-60HZ |

Voltage | 120W |

Alarm | Release alarm signal to controller or automatic reject system or stop with alarm |

Working Environment | -20℃~50℃; Humidity below90% |

Size and Sensitivity

Tunnel Width | Tunnel Height | Suitable conveyor width | Passing height | Sensitivity | |

1000mm | 200mm | 800mm | 150mm | FeΦ≥2.6mm | SUSΦ≥4.0mm |

1000mm | 250mm | 800mm | 200mm | FeΦ≥3.5mm | SUSΦ≥5.3mm |

1000mm | 300mm | 800mm | 250mm | FeΦ≥4.2mm | SUSΦ≥6.3mm |

1000mm | 350mm | 600mm | 300mm | FeΦ≥4.5mm | SUSΦ≥6.5mm |

1000mm | 400mm | 600mm | 350mm | FeΦ≥5.2mm | SUSΦ≥7.8mm |

1000mm | 450mm | 600mm | 400mm | FeΦ≥6. 1mm | SUSΦ≥9.2mm |

1000mm | 500mm | 600mm | 450mm | FeΦ≥6.8mm | SUSΦ≥10.3mm |

1200mm | 200mm | 1000mm | 150mm | FeΦ≥2.9mm | SUSΦ≥4.4mm |

1200mm | 250mm | 1000mm | 200mm | FeΦ≥3.8mm | SUSΦ≥5.7mm |

1200mm | 300mm | 1000mm | 250mm | FeΦ≥4 5mm | SUSΦ≥6 8mm |

1200mm | 350mm | 800mm | 300mm | FeΦ≥5.0mm | SUSΦ≥7.5mm |

1200mm | 400mm | 800mm | 350mm | FeΦ≥5 6mm | SUSΦ≥8 4mm |

1200mm | 450mm | 800mm | 400mm | FeΦ≥6. 1mm | SUSΦ≥9.5mm |

1200mm | 500mm | 800mm | 450mm | FeΦ≥6.8mm | SUSΦ≥10.2mm |

1400mm | 200mm | 1200mm | 150mm | FeΦ≥3 2mm | SUSΦ≥5 5mm |

1400mm | 250mm | 1200mm | 200mm | FeΦ≥4. 1mm | SUSΦ≥6.5mm |

1400mm | 300mm | 1200mm | 250mm | FeΦ≥5 0mm | SUSΦ≥7 5mm |

1400mm | 350mm | 1000mm | 300mm | FeΦ≥5.4mm | SUSΦ≥8.5mm |

1400mm | 400mm | 1000mm | 350mm | FeΦ≥6.3mm | SUSΦ≥9.5mm |

1400mm | 450mm | 1000mm | 400mm | FeΦ≥7 7mm | SUSΦ≥11 5mm |

1400mm | 500mm | 1000mm | 450mm | FeΦ≥8.6mm | SUSΦ≥13.0mm |

1600mm | 400mm | 1200mm | 300mm | FeΦ≥7 0mm | SUSΦ≥12 5mm |

1600mm | 500mm | 1200mm | 400mm | FeΦ≥8.0mm | SUSΦ≥13.5mm |

1600mm | 600mm | 1200mm | 500mm | FeΦ≥9.0mm | SUSΦ≥15.5mm |

1600mm | 700mm | 1200mm | 600mm | FeΦ≥10 0mm | SUSΦ≥17 5mm |

1600mm | 800mm | 1200mm | 700mm | FeΦ≥11.0mm | SUSΦ≥18.5mm |

1600mm | 900mm | 1200mm | 800mm | FeΦ≥12 0mm | SUSΦ≥21 0mm |

1800mm | 400mm | 1400mm | 300mm | FeΦ≥8.0mm | SUSΦ≥12.0mm |

1800mm | 500mm | 1400mm | 400mm | FeΦ≥10.0mm | SUSΦ≥15.0mm |

1800mm | 600mm | 1400mm | 500mm | FeΦ≥12 0mm | SUSΦ≥18 0mm |

1800mm | 700mm | 1400mm | 600mm | FeΦ≥14.0mm | SUSΦ≥21.0mm |

1800mm | 800mm | 1400mm | 700mm | FeΦ≥16 0mm | SUSΦ≥24 0mm |

1800mm | 900mm | 1400mm | 800mm | FeΦ≥18.0mm | SUSΦ≥27.0mm |

1800mm | 1000mm | 1400mm | 900mm | FeΦ≥20.0mm | SUSΦ≥40.0mm |

2000mm | 400mm | 1600mm | 300mm | FeΦ≥9.0mm | SUSΦ≥18.0mm |

2000mm | 500mm | 1600mm | 400mm | FeΦ≥11.0mm | SUSΦ≥25.0mm |

2000mm | 600mm | 1600mm | 500mm | FeΦ≥13 0mm | SUSΦ≥30 0mm |

2000mm | 700mm | 1600mm | 600mm | FeΦ≥15.0mm | SUSΦ≥33.0mm |

2000mm | 800mm | 1600mm | 700mm | FeΦ≥17.0mm | SUSΦ≥38.0mm |

2000mm | 900mm | 1600mm | 800mm | FeΦ≥19.0mm | SUSΦ≥43.0mm |

2000mm | 1000mm | 1600mm | 900mm | FeΦ≥21.0mm | SUSΦ≥47.0mm |

2200mm | 400mm | 1800mm | 300mm | FeΦ≥10 0mm | SUSΦ≥25 0mm |

2200mm | 500mm | 1800mm | 400mm | FeΦ≥12.0mm | SUSΦ≥30.0mm |

2200mm | 600mm | 1800mm | 500mm | FeΦ≥14 0mm | SUSΦ≥35 0mm |

2200mm | 700mm | 1800mm | 600mm | FeΦ≥16.0mm | SUSΦ≥40.0mm |

2200mm | 800mm | 1800mm | 700mm | FeΦ≥18.0mm | SUSΦ≥45.0mm |

2200mm | 900mm | 1800mm | 800mm | FeΦ≥20 0mm | SUSΦ≥50 0mm |

2200mm | 1000mm | 1800mm | 900mm | FeΦ≥22.0mm | SUSΦ≥55.0mm |

2400mm | 400mm | 2000mm | 300mm | FeΦ≥12 0mm | SUSΦ≥30 0mm |

2400mm | 500mm | 2000mm | 400mm | FeΦ≥14.0mm | SUSΦ≥35.0mm |

2400mm | 600mm | 2000mm | 500mm | FeΦ≥16.0mm | SUSΦ≥40.0mm |

2400mm | 700mm | 2000mm | 600mm | FeΦ≥18 0mm | SUSΦ≥45 0mm |

2400mm | 800mm | 2000mm | 700mm | FeΦ≥20.0mm | SUSΦ≥50.0mm |

2400mm | 900mm | 2000mm | 800mm | FeΦ≥22 0mm | SUSΦ≥55 0mm |

2400mm | 1000mm | 2000mm | 950mm | FeΦ≥24.0mm | SUSΦ≥60.0mm |

Notes:

4. All the sensitivity parameters above is on the basis of the test card detected on conveyor belt; while the actual sensitivity will be affected by the product’s features and working environment.

5. Above technical parameters are some ordinary models, if you want to know more different technical parameters, please consult our employees.

6. Products will constantly upgrade; please refer to our newest technical parameters for changes on parameters.

Specification

1.Structure:

Technical Parameter

Name | Parameter |

Detecting Height | 200mm (over 200mm, can be customized) |

Detecting Width | 500mm (over 500mm, can be customized) |

Sensitivity | Decided by the width and height of tunnel, refer to below sheet |

Power Supply | AC220V±10%,50-60HZ |

Voltage | 120W |

Alarm | Release alarm signal to controller or automatic reject system or stop with alarm |

Working Environment | -20℃~50℃; Humidity below90% |

Size and Sensitivity

Tunnel Width | Tunnel Height | Suitable conveyor width | Passing height | Sensitivity | |

1000mm | 200mm | 800mm | 150mm | FeΦ≥2.6mm | SUSΦ≥4.0mm |

1000mm | 250mm | 800mm | 200mm | FeΦ≥3.5mm | SUSΦ≥5.3mm |

1000mm | 300mm | 800mm | 250mm | FeΦ≥4.2mm | SUSΦ≥6.3mm |

1000mm | 350mm | 600mm | 300mm | FeΦ≥4.5mm | SUSΦ≥6.5mm |

1000mm | 400mm | 600mm | 350mm | FeΦ≥5.2mm | SUSΦ≥7.8mm |

1000mm | 450mm | 600mm | 400mm | FeΦ≥6. 1mm | SUSΦ≥9.2mm |

1000mm | 500mm | 600mm | 450mm | FeΦ≥6.8mm | SUSΦ≥10.3mm |

1200mm | 200mm | 1000mm | 150mm | FeΦ≥2.9mm | SUSΦ≥4.4mm |

1200mm | 250mm | 1000mm | 200mm | FeΦ≥3.8mm | SUSΦ≥5.7mm |

1200mm | 300mm | 1000mm | 250mm | FeΦ≥4 5mm | SUSΦ≥6 8mm |

1200mm | 350mm | 800mm | 300mm | FeΦ≥5.0mm | SUSΦ≥7.5mm |

1200mm | 400mm | 800mm | 350mm | FeΦ≥5 6mm | SUSΦ≥8 4mm |

1200mm | 450mm | 800mm | 400mm | FeΦ≥6. 1mm | SUSΦ≥9.5mm |

1200mm | 500mm | 800mm | 450mm | FeΦ≥6.8mm | SUSΦ≥10.2mm |

1400mm | 200mm | 1200mm | 150mm | FeΦ≥3 2mm | SUSΦ≥5 5mm |

1400mm | 250mm | 1200mm | 200mm | FeΦ≥4. 1mm | SUSΦ≥6.5mm |

1400mm | 300mm | 1200mm | 250mm | FeΦ≥5 0mm | SUSΦ≥7 5mm |

1400mm | 350mm | 1000mm | 300mm | FeΦ≥5.4mm | SUSΦ≥8.5mm |

1400mm | 400mm | 1000mm | 350mm | FeΦ≥6.3mm | SUSΦ≥9.5mm |

1400mm | 450mm | 1000mm | 400mm | FeΦ≥7 7mm | SUSΦ≥11 5mm |

1400mm | 500mm | 1000mm | 450mm | FeΦ≥8.6mm | SUSΦ≥13.0mm |

1600mm | 400mm | 1200mm | 300mm | FeΦ≥7 0mm | SUSΦ≥12 5mm |

1600mm | 500mm | 1200mm | 400mm | FeΦ≥8.0mm | SUSΦ≥13.5mm |

1600mm | 600mm | 1200mm | 500mm | FeΦ≥9.0mm | SUSΦ≥15.5mm |

1600mm | 700mm | 1200mm | 600mm | FeΦ≥10 0mm | SUSΦ≥17 5mm |

1600mm | 800mm | 1200mm | 700mm | FeΦ≥11.0mm | SUSΦ≥18.5mm |

1600mm | 900mm | 1200mm | 800mm | FeΦ≥12 0mm | SUSΦ≥21 0mm |

1800mm | 400mm | 1400mm | 300mm | FeΦ≥8.0mm | SUSΦ≥12.0mm |

1800mm | 500mm | 1400mm | 400mm | FeΦ≥10.0mm | SUSΦ≥15.0mm |

1800mm | 600mm | 1400mm | 500mm | FeΦ≥12 0mm | SUSΦ≥18 0mm |

1800mm | 700mm | 1400mm | 600mm | FeΦ≥14.0mm | SUSΦ≥21.0mm |

1800mm | 800mm | 1400mm | 700mm | FeΦ≥16 0mm | SUSΦ≥24 0mm |

1800mm | 900mm | 1400mm | 800mm | FeΦ≥18.0mm | SUSΦ≥27.0mm |

1800mm | 1000mm | 1400mm | 900mm | FeΦ≥20.0mm | SUSΦ≥40.0mm |

2000mm | 400mm | 1600mm | 300mm | FeΦ≥9.0mm | SUSΦ≥18.0mm |

2000mm | 500mm | 1600mm | 400mm | FeΦ≥11.0mm | SUSΦ≥25.0mm |

2000mm | 600mm | 1600mm | 500mm | FeΦ≥13 0mm | SUSΦ≥30 0mm |

2000mm | 700mm | 1600mm | 600mm | FeΦ≥15.0mm | SUSΦ≥33.0mm |

2000mm | 800mm | 1600mm | 700mm | FeΦ≥17.0mm | SUSΦ≥38.0mm |

2000mm | 900mm | 1600mm | 800mm | FeΦ≥19.0mm | SUSΦ≥43.0mm |

2000mm | 1000mm | 1600mm | 900mm | FeΦ≥21.0mm | SUSΦ≥47.0mm |

2200mm | 400mm | 1800mm | 300mm | FeΦ≥10 0mm | SUSΦ≥25 0mm |

2200mm | 500mm | 1800mm | 400mm | FeΦ≥12.0mm | SUSΦ≥30.0mm |

2200mm | 600mm | 1800mm | 500mm | FeΦ≥14 0mm | SUSΦ≥35 0mm |

2200mm | 700mm | 1800mm | 600mm | FeΦ≥16.0mm | SUSΦ≥40.0mm |

2200mm | 800mm | 1800mm | 700mm | FeΦ≥18.0mm | SUSΦ≥45.0mm |

2200mm | 900mm | 1800mm | 800mm | FeΦ≥20 0mm | SUSΦ≥50 0mm |

2200mm | 1000mm | 1800mm | 900mm | FeΦ≥22.0mm | SUSΦ≥55.0mm |

2400mm | 400mm | 2000mm | 300mm | FeΦ≥12 0mm | SUSΦ≥30 0mm |

2400mm | 500mm | 2000mm | 400mm | FeΦ≥14.0mm | SUSΦ≥35.0mm |

2400mm | 600mm | 2000mm | 500mm | FeΦ≥16.0mm | SUSΦ≥40.0mm |

2400mm | 700mm | 2000mm | 600mm | FeΦ≥18 0mm | SUSΦ≥45 0mm |

2400mm | 800mm | 2000mm | 700mm | FeΦ≥20.0mm | SUSΦ≥50.0mm |

2400mm | 900mm | 2000mm | 800mm | FeΦ≥22 0mm | SUSΦ≥55 0mm |

2400mm | 1000mm | 2000mm | 950mm | FeΦ≥24.0mm | SUSΦ≥60.0mm |

Notes:

4. All the sensitivity parameters above is on the basis of the test card detected on conveyor belt; while the actual sensitivity will be affected by the product’s features and working environment.

5. Above technical parameters are some ordinary models, if you want to know more different technical parameters, please consult our employees.

6. Products will constantly upgrade; please refer to our newest technical parameters for changes on parameters.