| Availability: | |

|---|---|

| Quantity: | |

AEC500C

COSO

Product Description

A metal detector is an electronic equipment used to detect metallic contaminants in raw materials or products.

Our metal detectors are suitable for various industries like food, pharmaceutical, plastic, daily chemical, textile, recycling, electronics, etc. It effectively detects impurities like ferrous, copper, SUS, aluminum and so on. When metal is detected, the equipment produces an audio signal and visual indicator to alert the user, belt stops or automatic rejection can be customized. By incorporating metal detector, businesses can ensure compliance with industry standards like HACCP, GMP, QS and ISO9001. This technology helps manufacturers reduce the risk of product recalls, minimize downtime and maintain smooth production processes.

Product Application

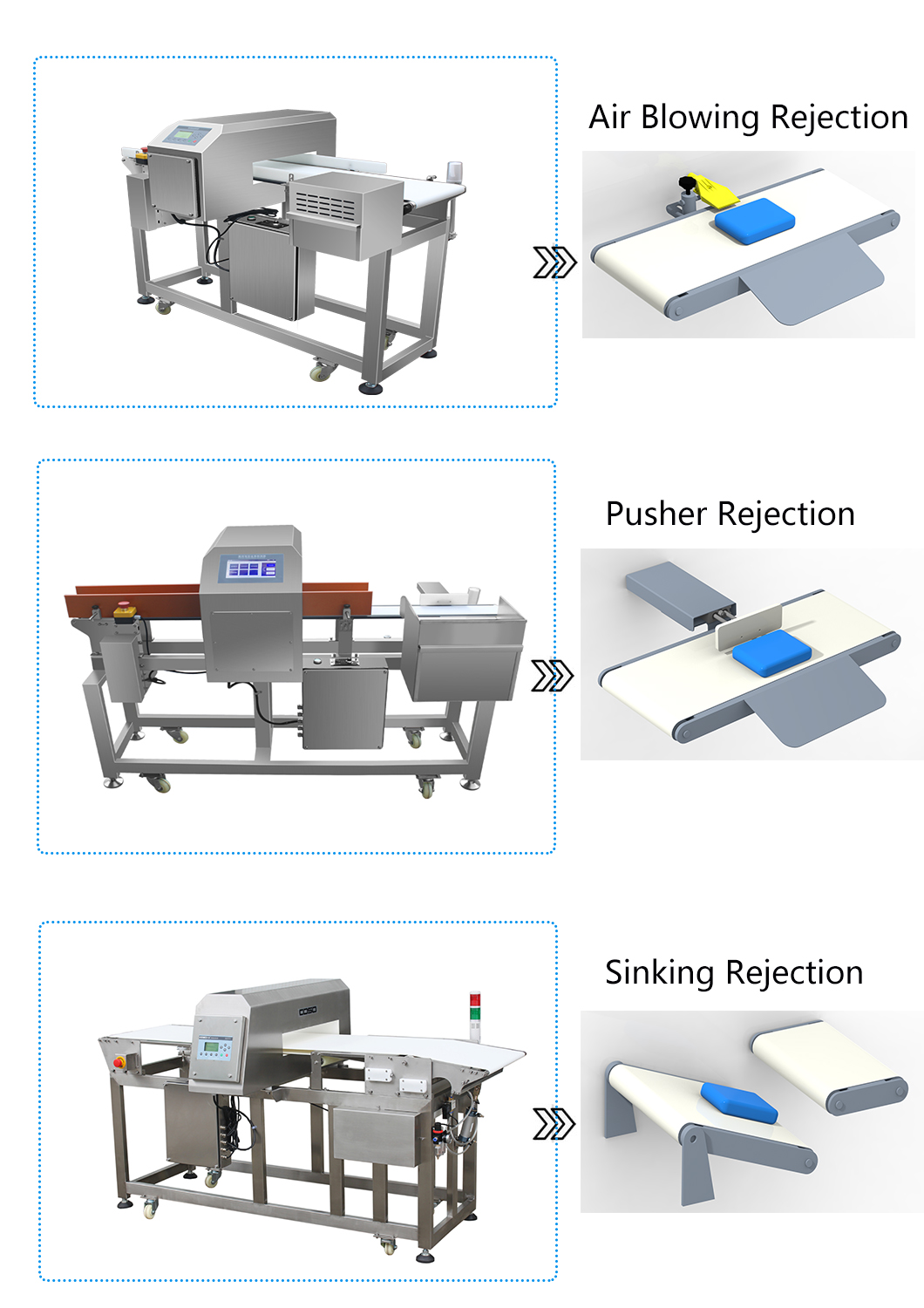

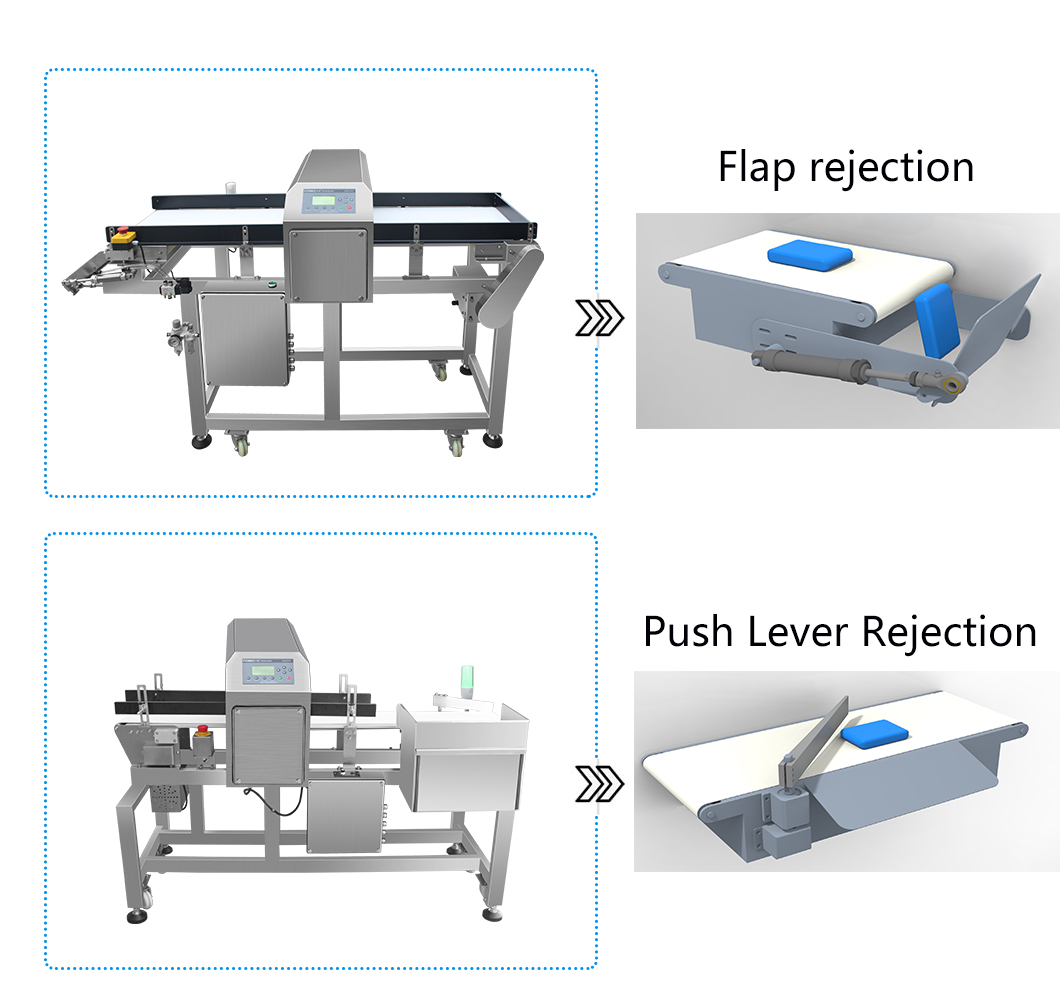

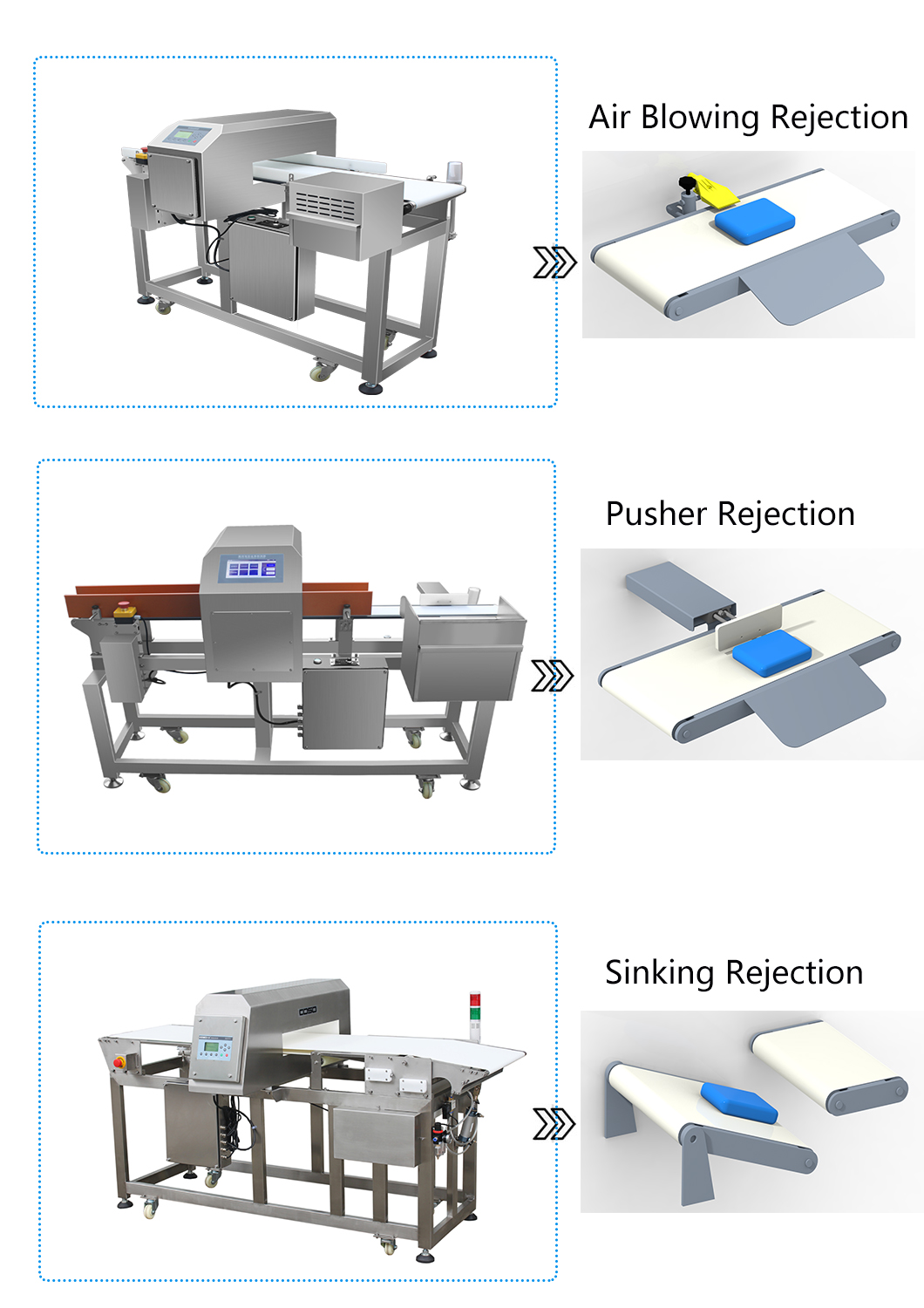

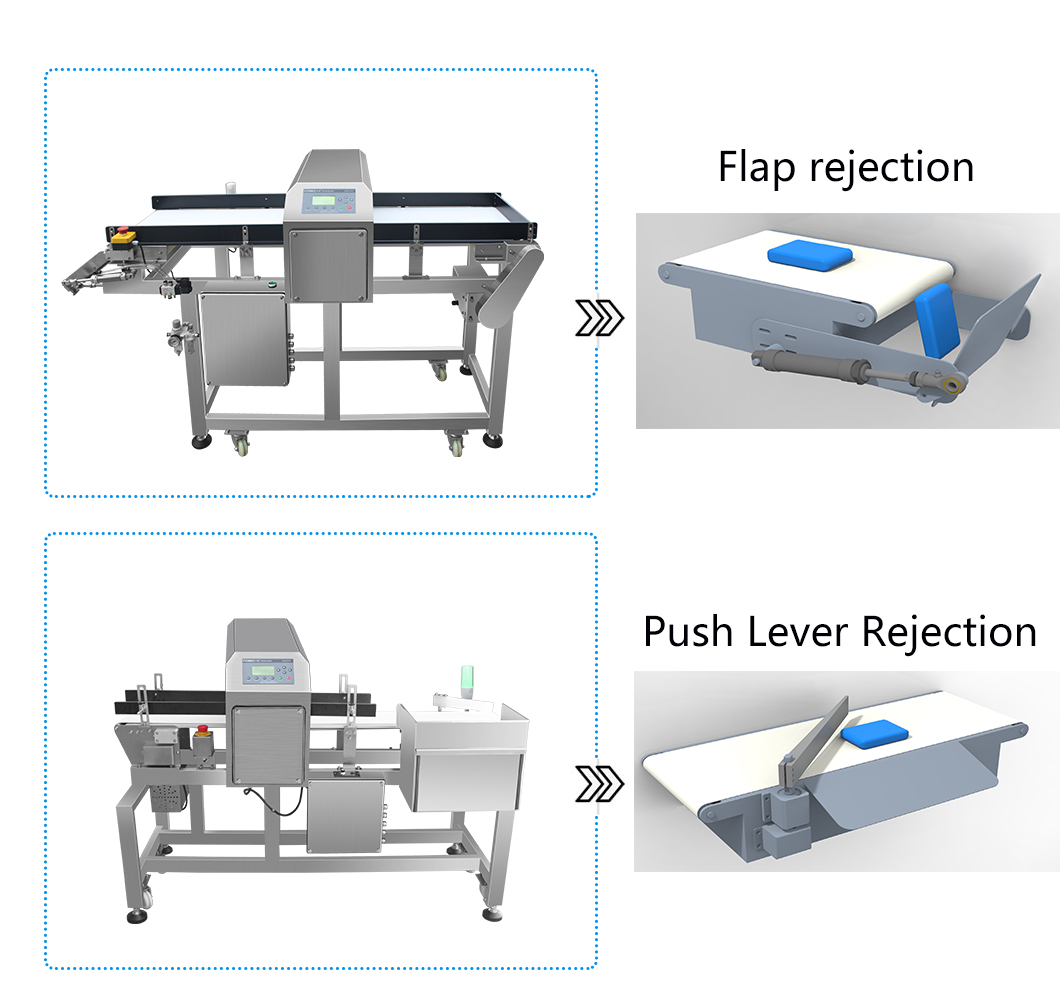

Optional Rejection

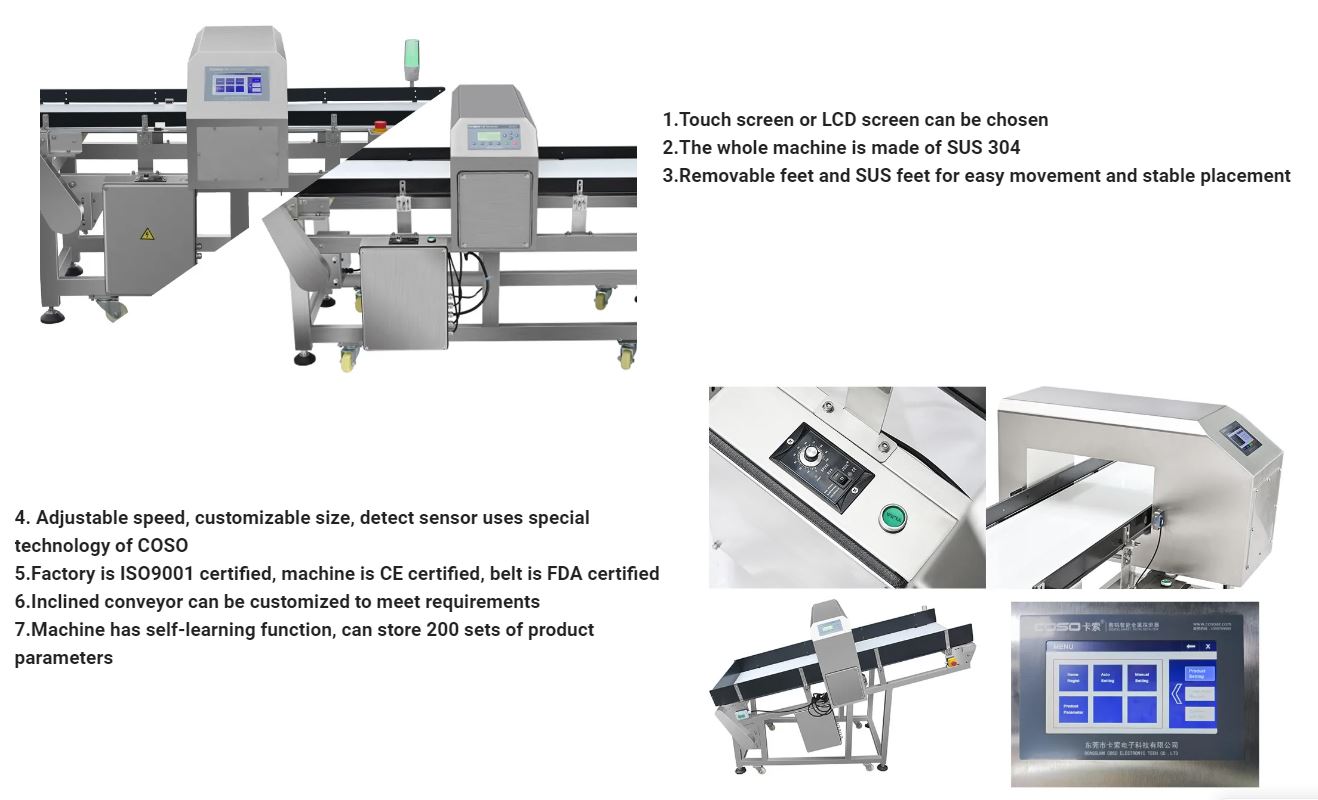

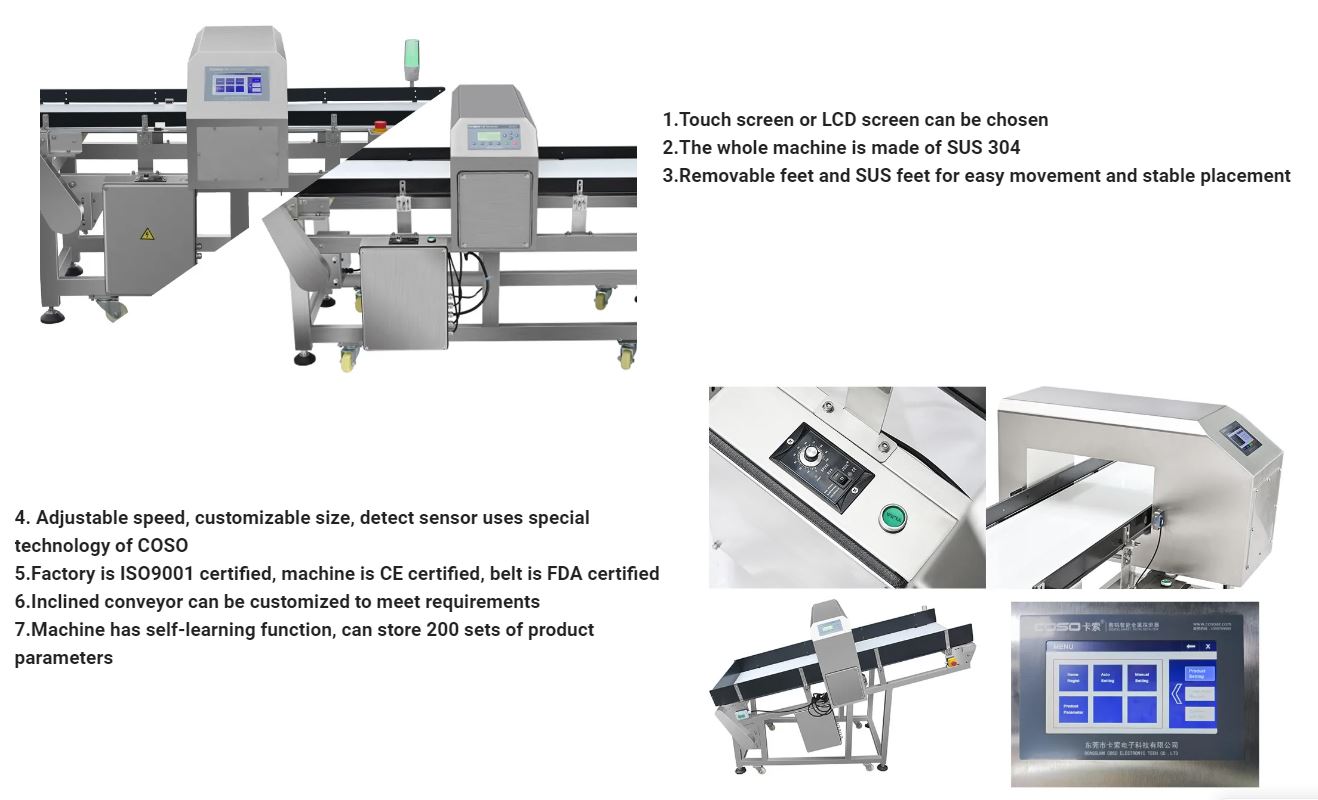

Product Feature

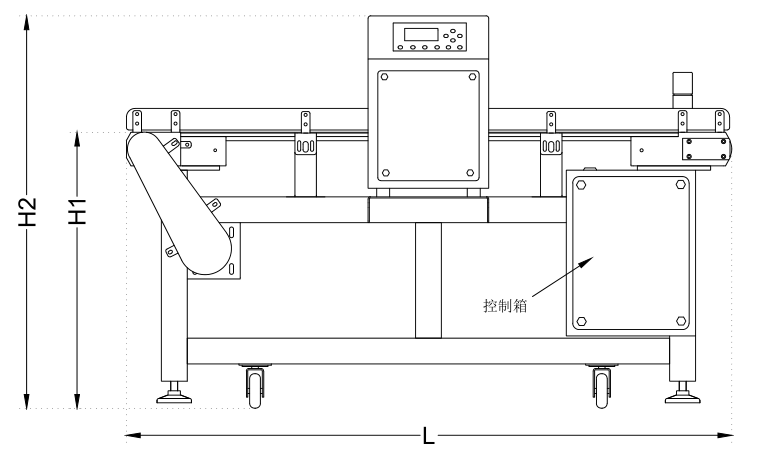

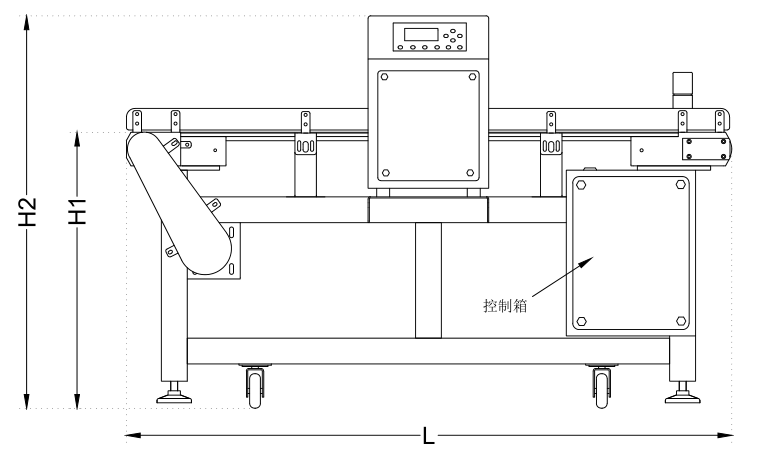

Product Parameters

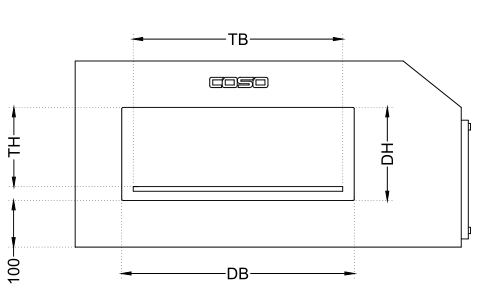

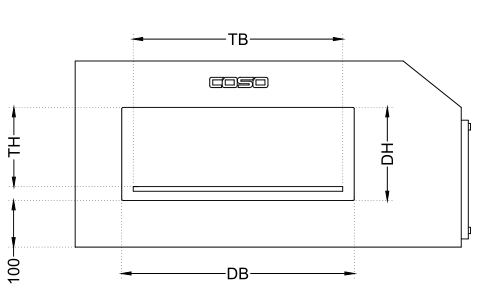

DB: Width of detector H1:Height from conveyor belt to the ground

DH:Height of detector H2:Height of whole machine

TB:Passing width L:Length of conveyor belt

TH:Passing height W:Height of whole machine

| Model | Size of whole machine(mm) | Size of detector(mm) | Sensitivity(mm) | |||||||

| H1 | H2 | L | W | DB | TB | DH | TH | Fe | SUS | |

| 3008 | 700 | 850 | 1200 | 650 | 300 | 250 | 80 | 50 | 0.5 | 1.0 |

| 3010 | 700 | 870 | 1200 | 650 | 300 | 250 | 100 | 70 | 0.6 | 1.2 |

| 3012 | 700 | 890 | 1200 | 650 | 300 | 250 | 120 | 90 | 0.7 | 1.4 |

| 3015 | 700 | 920 | 1200 | 650 | 300 | 250 | 150 | 120 | 0.8 | 1.5 |

| 4510 | 700 | 900 | 1400 | 750 | 450 | 400 | 100 | 70 | 0.6 | 1.3 |

| 4512 | 700 | 920 | 1400 | 750 | 450 | 400 | 120 | 90 | 0.7 | 1.4 |

| 4515 | 700 | 950 | 1400 | 750 | 450 | 400 | 150 | 120 | 0.8 | 1.5 |

| 5010 | 700 | 900 | 1500 | 850 | 500 | 450 | 100 | 70 | 0.6 | 1.3 |

| 5012 | 700 | 920 | 1500 | 850 | 500 | 450 | 120 | 90 | 0.8 | 1.4 |

| 5015 | 700 | 950 | 1500 | 850 | 500 | 450 | 150 | 120 | 1.0 | 1.5 |

| 5020 | 700 | 1000 | 1600 | 850 | 500 | 450 | 200 | 170 | 1.2 | 2.0 |

| 5025 | 700 | 1050 | 1600 | 850 | 500 | 450 | 250 | 220 | 1.5 | 2.5 |

| 5030 | 700 | 1100 | 1600 | 850 | 500 | 450 | 300 | 270 | 2.0 | 3.0 |

| 6030 | 400 | 800 | 1800 | 950 | 600 | 550 | 300 | 270 | 2.5 | 3.5 |

| 6035 | 400 | 850 | 1800 | 950 | 600 | 550 | 350 | 320 | 3.0 | 4.0 |

| 6040 | 400 | 900 | 2000 | 950 | 600 | 550 | 400 | 370 | 3.5 | 4.5 |

| 6050 | 400 | 950 | 2000 | 950 | 600 | 550 | 500 | 470 | 4.0 | 5.5 |

Notes:

1. All the sensitivity parameters above is on the basis of the test card detected on conveyor belt; while the actual sensitivity will be affected by the product's features and working environment.

2. Above technical parameters are some ordinary models, if you want to know more different technical parameters, please consult our employees.

3. Products will constantly upgrade; please refer to our newest technical parameters for changes on parameters.

Company Profile

Established in 2005, Dongguan Coso Electronic Tech Co., Ltd. is a professional detection equipment manufacturer. The factory is located in Dongguan, China, with convenient transportation access, covers an area of 6000 square meters.

We concentrate on industrial metal detector, metal separator, checkweigher, weight sorting machine, X-ray inspection system and needle detector. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction.With the strong ability of customization, we can provide professional solution to meet customers' requirements with competitive price.

The machine is easy to operate because of modular design and friendly HMl. We have professional engineers and experienced workers, which guarantee the quality, stability of equipments.

We warmly welcome customers to cooperate with us. lf you are interested in our machines, welcome your kind inquiry.

FAQ

Q1: Are you a manufacturer?

Yes, our factory was established in 2005, we specialize in design and production of detection equipments which have been exported to over 80 countries around the world.

Q2: What kind of service do you provide?

ODM, OEM and OBM.

Q3: How long is your delivery time?

Around 15 working days after receiving your deposit.

Q4: What's your minimum order quantity?

One set.

Q5: Do you accept customization?

Yes, all of our products can be customized according to customer's requirements.

Q6: How is your after-sales service?

Online technical support and instant communication are always available;

Our products have one-year warranty;

You can send people to our company for training;

We can send engineers to your company to help when needed.

Product Description

A metal detector is an electronic equipment used to detect metallic contaminants in raw materials or products.

Our metal detectors are suitable for various industries like food, pharmaceutical, plastic, daily chemical, textile, recycling, electronics, etc. It effectively detects impurities like ferrous, copper, SUS, aluminum and so on. When metal is detected, the equipment produces an audio signal and visual indicator to alert the user, belt stops or automatic rejection can be customized. By incorporating metal detector, businesses can ensure compliance with industry standards like HACCP, GMP, QS and ISO9001. This technology helps manufacturers reduce the risk of product recalls, minimize downtime and maintain smooth production processes.

Product Application

Optional Rejection

Product Feature

Product Parameters

DB: Width of detector H1:Height from conveyor belt to the ground

DH:Height of detector H2:Height of whole machine

TB:Passing width L:Length of conveyor belt

TH:Passing height W:Height of whole machine

| Model | Size of whole machine(mm) | Size of detector(mm) | Sensitivity(mm) | |||||||

| H1 | H2 | L | W | DB | TB | DH | TH | Fe | SUS | |

| 3008 | 700 | 850 | 1200 | 650 | 300 | 250 | 80 | 50 | 0.5 | 1.0 |

| 3010 | 700 | 870 | 1200 | 650 | 300 | 250 | 100 | 70 | 0.6 | 1.2 |

| 3012 | 700 | 890 | 1200 | 650 | 300 | 250 | 120 | 90 | 0.7 | 1.4 |

| 3015 | 700 | 920 | 1200 | 650 | 300 | 250 | 150 | 120 | 0.8 | 1.5 |

| 4510 | 700 | 900 | 1400 | 750 | 450 | 400 | 100 | 70 | 0.6 | 1.3 |

| 4512 | 700 | 920 | 1400 | 750 | 450 | 400 | 120 | 90 | 0.7 | 1.4 |

| 4515 | 700 | 950 | 1400 | 750 | 450 | 400 | 150 | 120 | 0.8 | 1.5 |

| 5010 | 700 | 900 | 1500 | 850 | 500 | 450 | 100 | 70 | 0.6 | 1.3 |

| 5012 | 700 | 920 | 1500 | 850 | 500 | 450 | 120 | 90 | 0.8 | 1.4 |

| 5015 | 700 | 950 | 1500 | 850 | 500 | 450 | 150 | 120 | 1.0 | 1.5 |

| 5020 | 700 | 1000 | 1600 | 850 | 500 | 450 | 200 | 170 | 1.2 | 2.0 |

| 5025 | 700 | 1050 | 1600 | 850 | 500 | 450 | 250 | 220 | 1.5 | 2.5 |

| 5030 | 700 | 1100 | 1600 | 850 | 500 | 450 | 300 | 270 | 2.0 | 3.0 |

| 6030 | 400 | 800 | 1800 | 950 | 600 | 550 | 300 | 270 | 2.5 | 3.5 |

| 6035 | 400 | 850 | 1800 | 950 | 600 | 550 | 350 | 320 | 3.0 | 4.0 |

| 6040 | 400 | 900 | 2000 | 950 | 600 | 550 | 400 | 370 | 3.5 | 4.5 |

| 6050 | 400 | 950 | 2000 | 950 | 600 | 550 | 500 | 470 | 4.0 | 5.5 |

Notes:

1. All the sensitivity parameters above is on the basis of the test card detected on conveyor belt; while the actual sensitivity will be affected by the product's features and working environment.

2. Above technical parameters are some ordinary models, if you want to know more different technical parameters, please consult our employees.

3. Products will constantly upgrade; please refer to our newest technical parameters for changes on parameters.

Company Profile

Established in 2005, Dongguan Coso Electronic Tech Co., Ltd. is a professional detection equipment manufacturer. The factory is located in Dongguan, China, with convenient transportation access, covers an area of 6000 square meters.

We concentrate on industrial metal detector, metal separator, checkweigher, weight sorting machine, X-ray inspection system and needle detector. Dedicated to strict quality control and thoughtful customer service, our experienced staff members are always available to discuss your requirements and ensure full customer satisfaction.With the strong ability of customization, we can provide professional solution to meet customers' requirements with competitive price.

The machine is easy to operate because of modular design and friendly HMl. We have professional engineers and experienced workers, which guarantee the quality, stability of equipments.

We warmly welcome customers to cooperate with us. lf you are interested in our machines, welcome your kind inquiry.

FAQ

Q1: Are you a manufacturer?

Yes, our factory was established in 2005, we specialize in design and production of detection equipments which have been exported to over 80 countries around the world.

Q2: What kind of service do you provide?

ODM, OEM and OBM.

Q3: How long is your delivery time?

Around 15 working days after receiving your deposit.

Q4: What's your minimum order quantity?

One set.

Q5: Do you accept customization?

Yes, all of our products can be customized according to customer's requirements.

Q6: How is your after-sales service?

Online technical support and instant communication are always available;

Our products have one-year warranty;

You can send people to our company for training;

We can send engineers to your company to help when needed.