| Availability: | |

|---|---|

| Quantity: | |

Digital intelligent metal detector with dropleaf rejection system

AEC500C Series digital intelligent conveyor belt metal detector can be used in food, pharmaceutical, chemical, textile, garment, toy paper-making, hygienic products, electronics, renewable resources industry etc, applying to detect broken needles, iron wires, metals (such as Plumbum; Copper; Aluminum; Stannum; SUS etc.) that mixed or left with products, raw materials. Using metal detector can help relative corporations pass HACCP,GMP, FDA,QS, ISO9001 certificate.

Principle for rejection system:

As picture shows, Green arrow → means moving direction for qualified products; Red arrow → shows the falling direction of unqualified products; Bi-directional arrow means the moving direction of reject system when detecting unqualified products containing metallic impurities.

Application:

Suitable for bulk, lightweight and easy-falling products; mainly applied to food, pharmaceutical, toys industry etc for automatic online metal detection.

Product features:

Metal detector adopts air-operated dropleaf reject system which can combine with production lines realizing full automation on online metal detection and automatic rejection on unqualified products.

Digital intelligent metal detector with dropleaf rejection system

AEC500C Series digital intelligent conveyor belt metal detector can be used in food, pharmaceutical, chemical, textile, garment, toy paper-making, hygienic products, electronics, renewable resources industry etc, applying to detect broken needles, iron wires, metals (such as Plumbum; Copper; Aluminum; Stannum; SUS etc.) that mixed or left with products, raw materials. Using metal detector can help relative corporations pass HACCP,GMP, FDA,QS, ISO9001 certificate.

Principle for rejection system:

As picture shows, Green arrow → means moving direction for qualified products; Red arrow → shows the falling direction of unqualified products; Bi-directional arrow means the moving direction of reject system when detecting unqualified products containing metallic impurities.

Application:

Suitable for bulk, lightweight and easy-falling products; mainly applied to food, pharmaceutical, toys industry etc for automatic online metal detection.

Product features:

Metal detector adopts air-operated dropleaf reject system which can combine with production lines realizing full automation on online metal detection and automatic rejection on unqualified products.

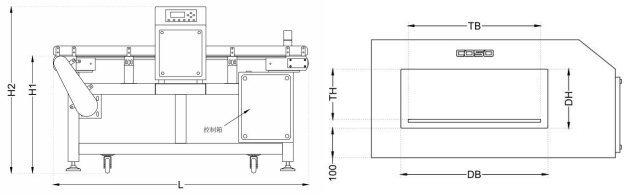

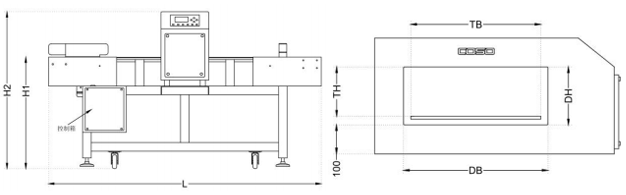

Structure:

DB: Width of detector H1:Height from conveyor belt to the ground

DH:Height of detector H2:Height of whole machine

TB:Passing width L:Length of conveyor belt

TH:Passing height W:Height of whole machine

For Lightweight Products

For Heavy-weight Products

Specification

Model | Size of whole machine(mm) | Size of detector(mm) | sensitivity | Max Weight(kg) | Speed(m/s) | Power supply | Working Environment | |||||||

H1 | H2 | L | W | DB | TB | DH | TH | Fe (mm) | SUS (mm) | |||||

3008 | 700 | 850 | 1200 | 650 | 300 | 250 | 80 | 50 | 0.6 | 1.0 | 0-25kg (can be customized) | 0.25- 0.6 |

AC220V±10% 50-60Hz |

-20℃~50℃ Humidity below 90% |

3010 | 700 | 870 | 1200 | 650 | 300 | 250 | 100 | 70 | 0.8 | 1.5 | ||||

3012 | 700 | 890 | 1200 | 650 | 300 | 250 | 120 | 90 | 0.8 | 1.8 | ||||

3015 | 700 | 920 | 1200 | 650 | 300 | 250 | 150 | 120 | 1.0 | 2.0 | ||||

4510 | 700 | 900 | 1400 | 750 | 450 | 400 | 100 | 70 | 0.6 | 1.5 | ||||

4512 | 700 | 920 | 1400 | 750 | 450 | 400 | 120 | 90 | 0.8 | 1.8 | ||||

4515 | 700 | 950 | 1400 | 750 | 450 | 400 | 150 | 120 | 1.0 | 2.0 | ||||

5010 | 700 | 900 | 1500 | 850 | 500 | 450 | 100 | 70 | 0.8 | 1.8 | ||||

5012 | 700 | 920 | 1500 | 850 | 500 | 450 | 120 | 90 | 1.0 | 1.8 | ||||

5015 | 700 | 950 | 1500 | 850 | 500 | 450 | 150 | 120 | 1.2 | 2.0 | ||||

5020 | 700 | 1000 | 1600 | 850 | 500 | 450 | 200 | 170 | 1.4 | 2.2 | ||||

5025 | 700 | 1050 | 1600 | 850 | 500 | 450 | 250 | 220 | 1.5 | 2.5 | ||||

5030 | 700 | 1100 | 1600 | 850 | 500 | 450 | 300 | 270 | 2.0 | 3.0 | ||||

6030 | 400 | 800 | 1800 | 950 | 600 | 550 | 300 | 270 | 2.5 | 3.5 | 25-200kg (can be customized) | 0.25- 0.6 | AC380V±10%, 50-60Hz | 0-40℃ Humidity below 80% |

6035 | 400 | 850 | 1800 | 950 | 600 | 550 | 350 | 320 | 3.0 | 4.0 | ||||

6040 | 400 | 900 | 2000 | 950 | 600 | 550 | 400 | 370 | 3.5 | 4.5 | ||||

6050 | 400 | 950 | 2000 | 950 | 600 | 550 | 500 | 470 | 4.0 | 5.5 | ||||

Notes:

1. All the sensitivity parameters above is on the basis of the test card detected on conveyor belt; while the actual sensitivity will be affected by the product’s features and working environment.

2. Above technical parameters are some ordinary models, if you want to know more different technical parameters, please consult our employees.

3. Products will constantly upgrade; please refer to our newest technical parameters for changes on parameters.

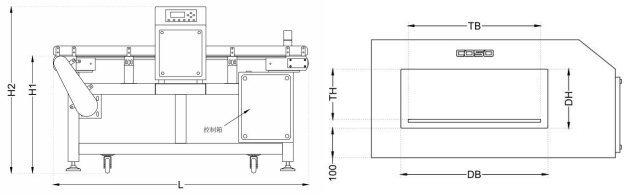

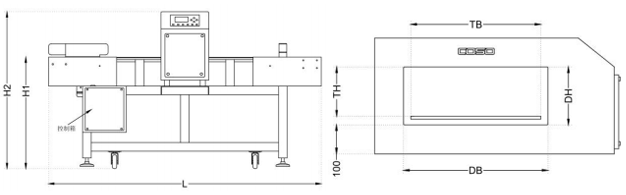

Structure:

DB: Width of detector H1:Height from conveyor belt to the ground

DH:Height of detector H2:Height of whole machine

TB:Passing width L:Length of conveyor belt

TH:Passing height W:Height of whole machine

For Lightweight Products

For Heavy-weight Products

Specification

Model | Size of whole machine(mm) | Size of detector(mm) | sensitivity | Max Weight(kg) | Speed(m/s) | Power supply | Working Environment | |||||||

H1 | H2 | L | W | DB | TB | DH | TH | Fe (mm) | SUS (mm) | |||||

3008 | 700 | 850 | 1200 | 650 | 300 | 250 | 80 | 50 | 0.6 | 1.0 | 0-25kg (can be customized) | 0.25- 0.6 |

AC220V±10% 50-60Hz |

-20℃~50℃ Humidity below 90% |

3010 | 700 | 870 | 1200 | 650 | 300 | 250 | 100 | 70 | 0.8 | 1.5 | ||||

3012 | 700 | 890 | 1200 | 650 | 300 | 250 | 120 | 90 | 0.8 | 1.8 | ||||

3015 | 700 | 920 | 1200 | 650 | 300 | 250 | 150 | 120 | 1.0 | 2.0 | ||||

4510 | 700 | 900 | 1400 | 750 | 450 | 400 | 100 | 70 | 0.6 | 1.5 | ||||

4512 | 700 | 920 | 1400 | 750 | 450 | 400 | 120 | 90 | 0.8 | 1.8 | ||||

4515 | 700 | 950 | 1400 | 750 | 450 | 400 | 150 | 120 | 1.0 | 2.0 | ||||

5010 | 700 | 900 | 1500 | 850 | 500 | 450 | 100 | 70 | 0.8 | 1.8 | ||||

5012 | 700 | 920 | 1500 | 850 | 500 | 450 | 120 | 90 | 1.0 | 1.8 | ||||

5015 | 700 | 950 | 1500 | 850 | 500 | 450 | 150 | 120 | 1.2 | 2.0 | ||||

5020 | 700 | 1000 | 1600 | 850 | 500 | 450 | 200 | 170 | 1.4 | 2.2 | ||||

5025 | 700 | 1050 | 1600 | 850 | 500 | 450 | 250 | 220 | 1.5 | 2.5 | ||||

5030 | 700 | 1100 | 1600 | 850 | 500 | 450 | 300 | 270 | 2.0 | 3.0 | ||||

6030 | 400 | 800 | 1800 | 950 | 600 | 550 | 300 | 270 | 2.5 | 3.5 | 25-200kg (can be customized) | 0.25- 0.6 | AC380V±10%, 50-60Hz | 0-40℃ Humidity below 80% |

6035 | 400 | 850 | 1800 | 950 | 600 | 550 | 350 | 320 | 3.0 | 4.0 | ||||

6040 | 400 | 900 | 2000 | 950 | 600 | 550 | 400 | 370 | 3.5 | 4.5 | ||||

6050 | 400 | 950 | 2000 | 950 | 600 | 550 | 500 | 470 | 4.0 | 5.5 | ||||

Notes:

1. All the sensitivity parameters above is on the basis of the test card detected on conveyor belt; while the actual sensitivity will be affected by the product’s features and working environment.

2. Above technical parameters are some ordinary models, if you want to know more different technical parameters, please consult our employees.

3. Products will constantly upgrade; please refer to our newest technical parameters for changes on parameters.